The ASS40K-12 is an older encoder model that has become increasingly difficult to purchase in recent years. Many users in the heavy industrial field have reported sourcing challenges for this model. To solve these issues, we provide a fully compatible 1:1 customized replacement solution for the ASS40K-12 encoder. Our product replicates the original mechanical dimensions, electrical interface, and signal output, ensuring seamless integration with existing systems. The entire manufacturing process is optimized for speed, allowing us to deliver replacement units in a very short lead time. This helps reduce machine downtime and ensures continued stable performance for customers who depend on this encoder in production environments.

In terms of application, the ASS40K-12 encoder is well-known for its reliability in harsh industrial environments such as steel plants, metallurgical equipment, and crane systems. Over the past few years, our customized replacement solution for the ASS40K-12 has been successfully applied in the Middle East, Russia, Southeast Asia, Indonesia, and South America. These markets have strong demand for heavy-duty encoders capable of long-term operation in high-temperature, high-vibration, or high-dust conditions. Customer feedback confirms that our replacement version performs with consistent precision, strong durability, and excellent compatibility, making it a reliable alternative to the original product.

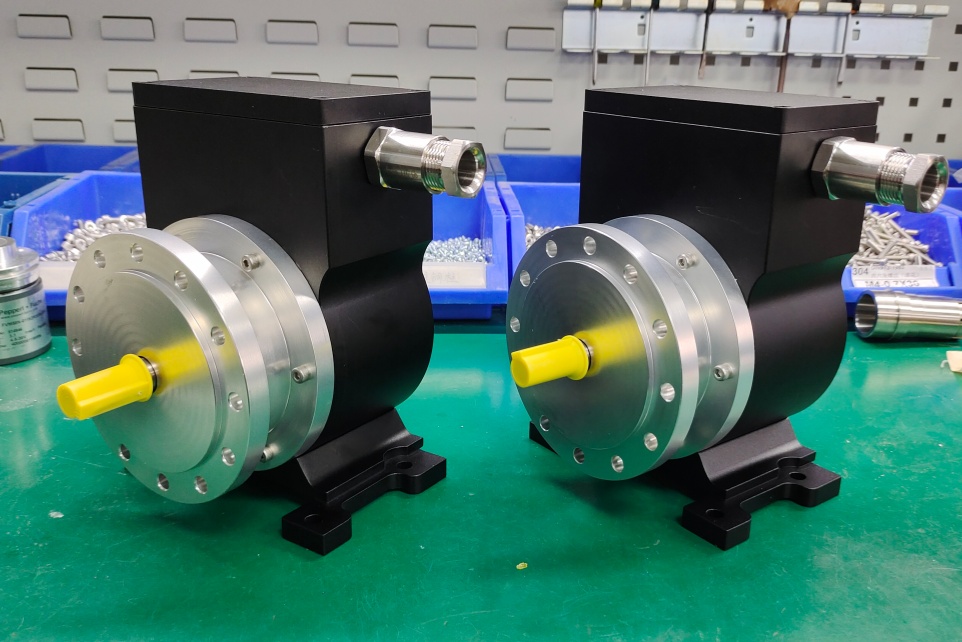

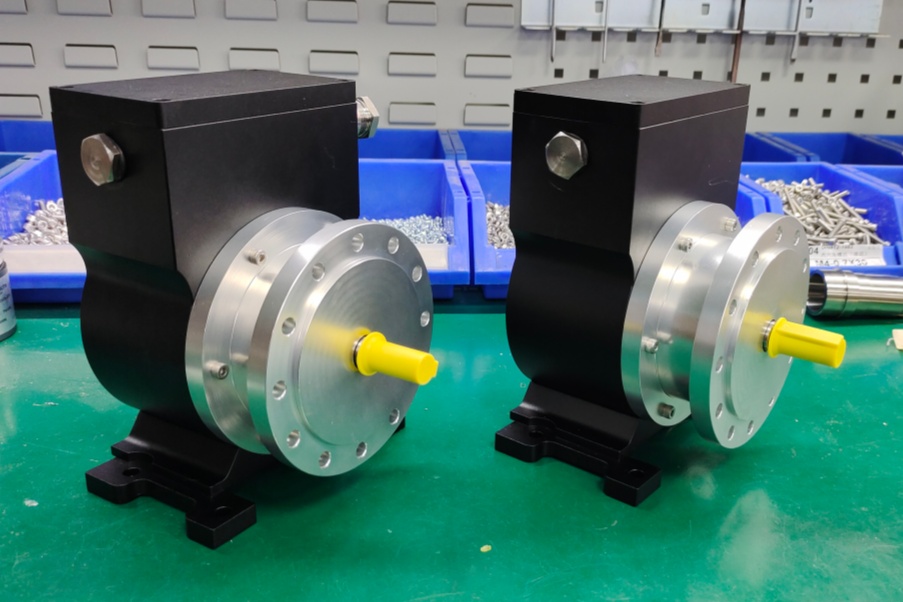

Replacement solution reference image.

Technical data

1. Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12…30 V DC |

| No-load power consumption | approx. 1 W |

| Resolution singleturn | Max. 16 bit (65536 steps per revolution) see type plate |

| Resolution multiturn | 12 bit (4096 revolutions) see type plate |

| Data format | SSI, binary/gray code (see type plate) |

2. SSI-Interface

| Parameter | Details |

|---|---|

| Clock input | RS 422 / 5V |

| Input current | 5 mA |

| Clock frequency | 80kHz…1 MHz |

| Clock rate/transmission | 25 / 13 (multiturn / singleturn) |

| SSI-time out | > 30 μs (without data repetition) < 20 μs (with data repetition) |

| Data interface | RS 422 / 5V |

3. Control signals

| Parameter | Details |

|---|---|

| V/IR, Z (input) | 5…30V / 5mA |

| State (output) | HTL |

| Temperature range | -25°C…+85°C; For UL and CSA -25°C…+70°C |

4. Degree of protection according to DIN EN 60529

| Degree of protection | Sealing | Mech. permissable speed | Rotor moment of inertia | Breakaway torque |

|---|---|---|---|---|

| IP 66 | with Labyrinth seal | ≤6000 rpm | approx. 580 gcm² | approx. 6 Nm |

| IP 66 / IP 67 | with axial shaft seal | ≤4000 rpm | approx. 510 gcm² | approx. 8 Nm |

| IP 66 / IP 67 | With radial shaft seal (for special applications, e.g. wet areas in rolling mills) | ≤3000 rpm | approx. 510 gcm² | approx. 9 Nm |

5. Vibration resistance, shock resistance and shaft load

| Parameter | Standard | Value |

|---|---|---|

| Vibration resistance | DIN EN 60068-2-6 / IEC 68-2-6 (10 … 2000 Hz) | 20 g (=200 m/s²) |

| Shock resistance | DIN EN 60068-2-27 / IEC 68-2-27 (6 ms) | 150 g (=1500 m/s²) |

| Max. encoder shaft load | - | Fₐ, max. (axial) = 100 N; Fᵣ, max. (radial) = 120 N |

6. Shaft dimensions

| Parameter | Details |

|---|---|

| Shaft dimensions | 11j6 x 30 mm (standard); 14j6 x 30 mm (optional) |

7. Weight

| Parameter | Type | Details |

|---|---|---|

| Weight | Type K (construction type B5) | approx. 3.1 kg |