إن FG4KK-16384G-90G-NG is a high-resolution heavy-duty incremental encoder engineered for critical applications in the steel and metallurgy industry. With an impressive 16,384 pulses per revolution, it provides ultra-precise feedback required for controlling rolling mills, continuous casting systems, large industrial drives, and high-speed automation processes. Its robust construction allows it to endure the harsh conditions often encountered in steel plants, including high temperatures, heavy vibrations, and continuous operation under full load.

Due to its status as a legacy model, sourcing the original FG4KK-16384G-90G-NG has become increasingly difficult. To address this challenge, we have developed a custom replacement encoder that replicates the original’s specifications exactly. This includes mechanical dimensions, electrical interfaces, signal output characteristics, and rotational accuracy, ensuring a direct drop-in solution without requiring modifications to existing equipment or control systems.

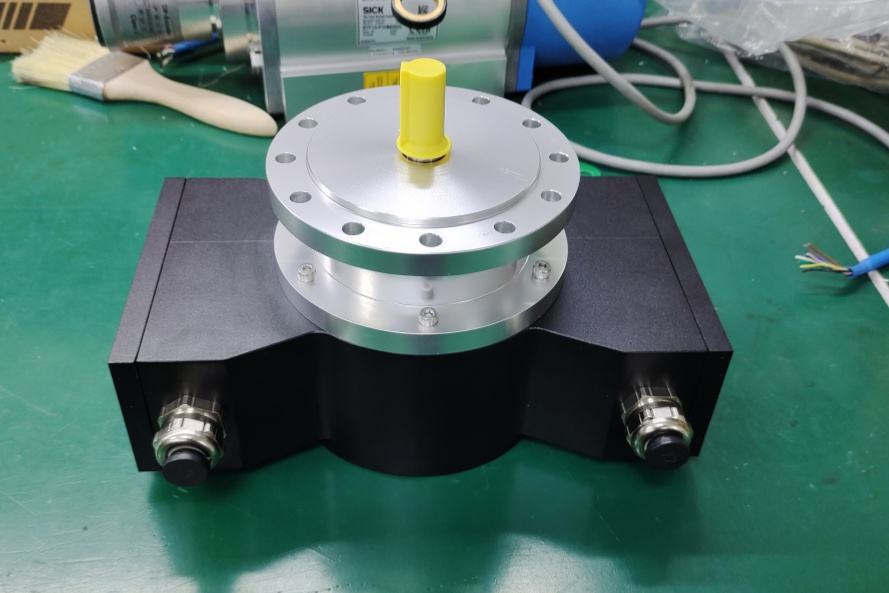

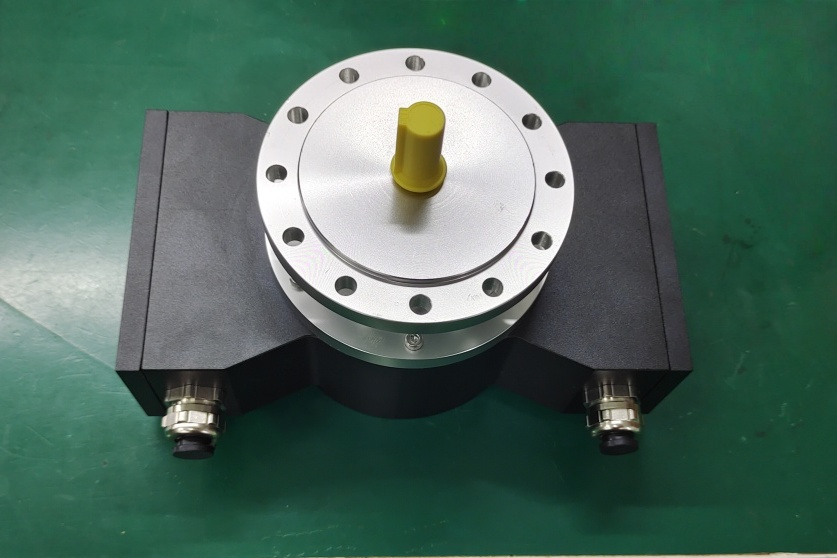

Alternative Solution Product Image

Applications:

- Rolling mills for real-time speed and position monitoring

- Continuous casting systems for precise alignment and process control

- Heavy-duty industrial drives in metallurgical and steel production

- Automation and process control systems requiring high-resolution feedback

Expert’s note: The FG4KK-16384G-90G-NG replacement excels in precision and reliability, critical for high-value steel manufacturing operations. Its heavy-duty design ensures continuous operation with minimal maintenance, while our custom service allows clients to tailor encoders for unique operational requirements, securing long-term equipment uptime and consistent process quality.

To address supply shortages and tight delivery schedules, we offer custom non-standard replacement services for the FG4KK-16384G-90G-NG. This service allows clients to request units tailored to their specific requirements, ensuring compatibility and reliability. Our typical lead time for non-standard orders is 15 working days, providing a fast and efficient solution for operators facing difficulties sourcing legacy encoders. By leveraging this service, steel and metallurgy plants can maintain production continuity and reduce downtime.

ورقة البيانات الفنية

Pulse rates

| Category | Value |

|---|---|

| Standard pulse rates | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Special pulse rates | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000(further pulse rates according to customers specification) |

Connection data

| المعلمة | التفاصيل |

|---|---|

| جهد الإمداد | 12 V … 30 V DCFor UL and CSA Class 2 supplied |

| No load-current | approx. 50 mA at 24 V |

| Outputs | Current limited, short-circuit proof push-pull line driver with integrated impedance adaptation for 30 to 140 Ω lines. |

| Pulse height (HTL) | approx. as supply voltage, output saturation voltage < 0.4 V at Iₗ 30 mA |

| Output current | max. 150 mA at 24 V (observe derating) |

| Internal resistance | 75 Ω bei 24 V |

| Slew rate | 200 V / μs with Cₗ 100 pF |

| Duty cycle | 1:1 ± 3 % for standard pulse rates1:1 ± 5 % for special pulse rates up to 25000 pulses |

| Square wave displacement 0°, 90° | 90° ± 3 % for standard pulse rates90° ± 5 % for special pulse rates up to 25000 pulses |

| Max. frequency | 200 kHz, Higher max. frequency on request |

Special output voltage 5V (TTL)

| المعلمة | التفاصيل |

|---|---|

| Pulse height | 5V, RS422-compatible (TIA/EIA - Standard) |

| جهد الإمداد | 12 … 30 V DC (optional: 5 V DC)For UL and CSA Class 2 supplied |