For customers who are unable to source the M6-5S3XH51-W005 petroleum winch encoder, we provide a specialized non-standard customized replacement solution. Unlike mass-produced inventory-based supply, our method focuses on tailored manufacturing to guarantee a precise match with the original mechanical specifications and electrical performance. This process gives end users the flexibility to secure replacement encoders without facing excessive delays caused by limited market availability. In general, our standard production cycle is about 15 working days, which allows us to deliver compatible units within a relatively short timeframe. By choosing a customized approach rather than relying on large stock levels, we can effectively address urgent procurement challenges, minimize downtime, and help customers maintain continuous operation of their critical oilfield equipment.

The M6-5S3XH51-W005 belongs to a family of encoders designed to withstand the extreme demands of oilfield drilling and winch operations, where accurate incremental feedback is essential for controlling heavy loads and ensuring safe lifting performance. Petroleum winches operate under harsh conditions including constant vibration, shock, exposure to oil, dust, and outdoor weather, which require encoders with exceptional durability and reliability. In these scenarios, the encoder’s role is vital for monitoring drum rotation and providing stable position feedback, directly contributing to safe and efficient drilling operations. By offering a fully compatible replacement, we ensure that operators in oil and gas exploration, offshore drilling platforms, and related heavy industries can rely on consistent signal output, robust construction, and dependable integration with existing control systems. Our replacement solutions not only extend equipment life but also safeguard productivity and worker safety in demanding oilfield environments.

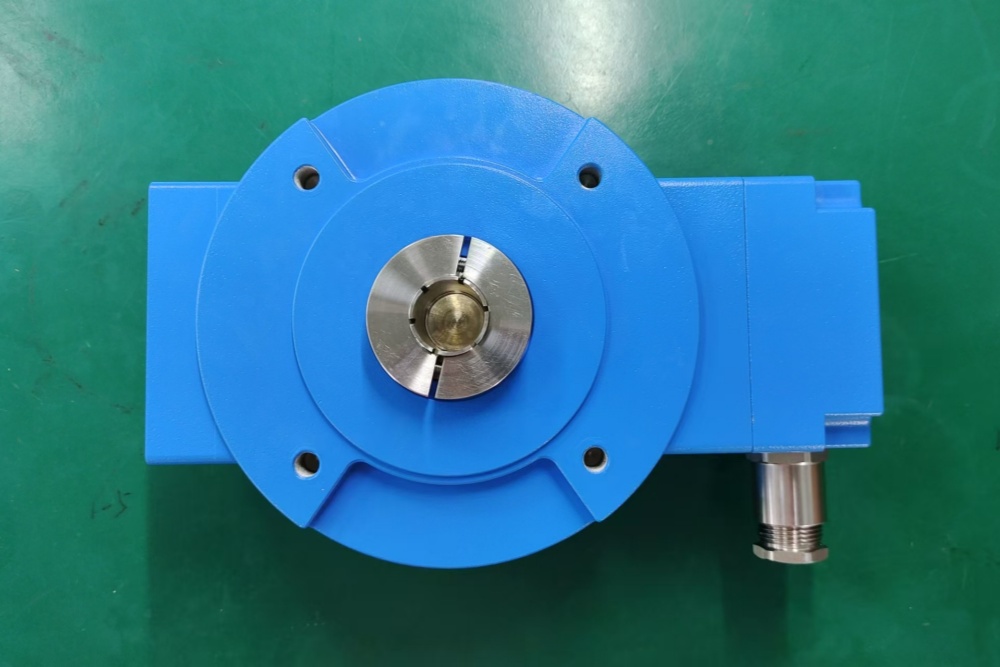

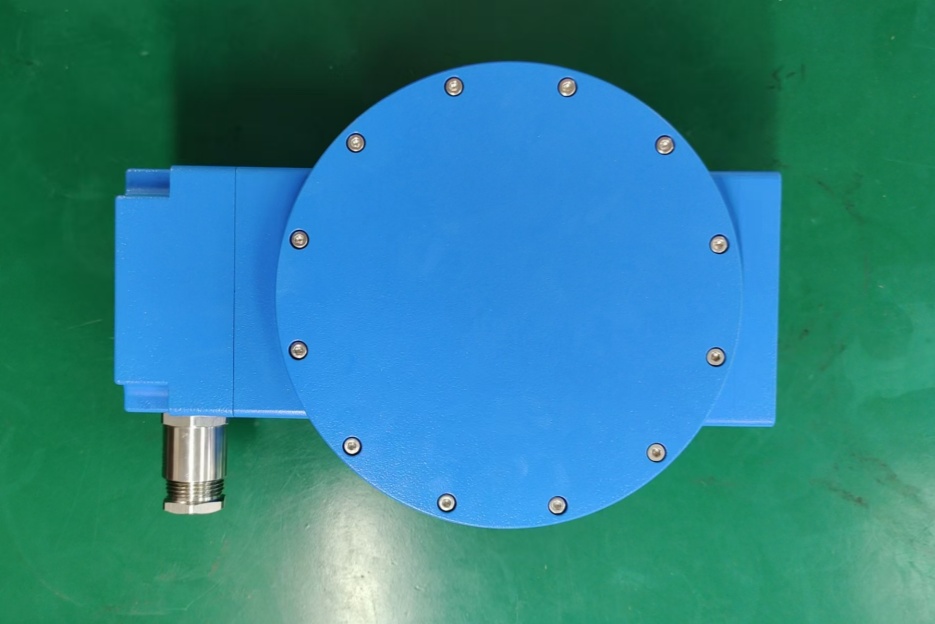

Actual photos of the replacement product.

Product Description

The M6-5S3XH51-T005 is an explosion-proof hollow-shaft incremental encoder, designed for petroleum winches and other demanding industrial applications. Utilizing magnetoresistive sensing technology, it ensures high reliability and strong resistance to contamination and vibration. Certified according to ATEX standards, it is suitable for hazardous environments (Zone 1, Gas Group IIC).

The hollow-shaft design eliminates couplings and flanges, simplifying installation. An anti-rotation bracket is included to absorb shaft end float while preventing housing rotation.

Key Features

- Explosion-Proof Certified: Compliant with EN60079-0, EN60079-1, EN60079-7, ATEX II 2G Ex de IIC T4 Gb

- Rugged Construction: IP66-rated enclosure, cast aluminum housing, dustproof and waterproof

- Magnetoresistive Sensing: Reliable in contaminated and high-vibration industrial environments

- Flexible Outputs: Single-ended or differential (A/B, optional Z marker)

- Multiple Resolutions: 240, 256, 300, 480, 512, 600, 960, 1024, 1200 PPR available

- Dual Output Capability: Provides two different PPR signals simultaneously

- Wide Voltage Range: 5–24 VDC, with built-in short-circuit and reverse polarity protection

Technical Specifications

- Electrical

- Supply Voltage: 5–24 VDC

- Current Consumption: 120mA (no load)

- Output Signal: Square wave, 50 ±10% duty cycle

- Max Frequency: 150 kHz

- Resolution: 1024 PPR

- Mechanical

- Hollow Shaft Diameter: 1-1/8" (28.6 mm)

- Max Speed: 5000 RPM

- Starting Torque: 1.5–20 oz·in

- Bearing Life: 6.1 × 10⁹ revolutions (no extra load)

- Weight: ≤ 18 lbs

- Environmental

- Operating Temperature: -20°C ~ +80°C (optional -40°C ~ +80°C)

- Protection Class: IP66

- Hazardous Area: Zone 1, Ex de IIC T4 Gb