The FG40K-2500G-90G-NG is a mid-resolution incremental encoder widely used in steel plants, rolling mills, and metallurgical automation systems. With 2500 pulses per revolution, it balances precision, performance, and cost-effectiveness for industrial operations.

It is particularly valued for its rugged construction, allowing consistent operation in environments exposed to vibration, high temperatures, and airborne contaminants. Its performance ensures accurate motor feedback, conveyor monitoring, and drive synchronization, even in the harshest conditions.

Technically, the encoder provides stable and reliable signal output, suitable for medium-resolution speed control and positioning tasks. It is often applied to rolling lines, casting processes, and heavy-duty drives, where accurate feedback is critical for operational efficiency.

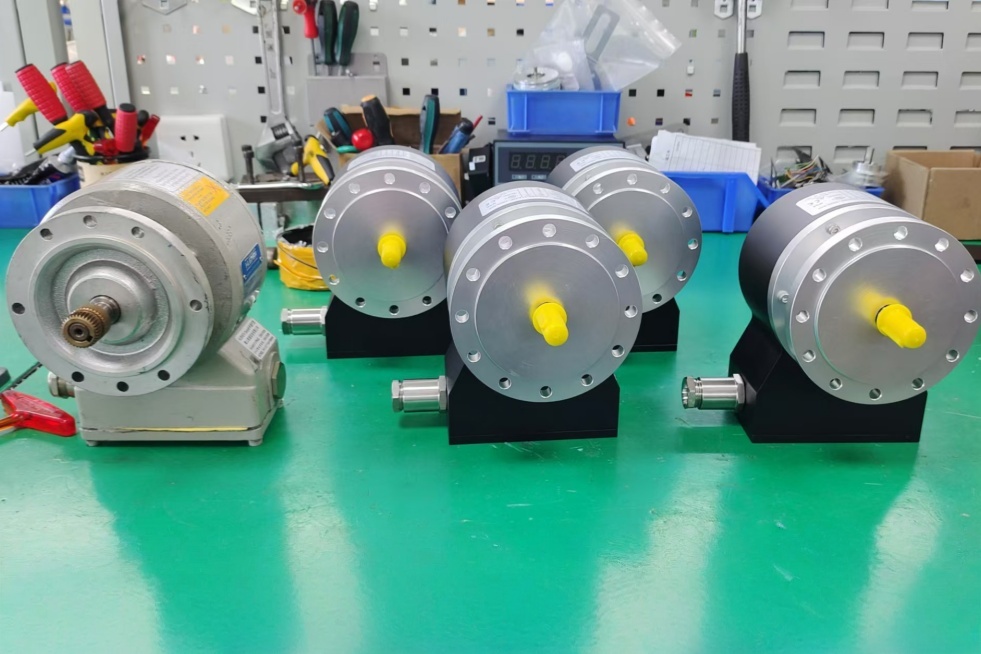

Given current supply chain limitations, obtaining the FG40K-2500G-90G-NG quickly can be difficult. To mitigate this, we provide a custom replacement solution designed to match the original specifications exactly. This allows operators to integrate the replacement seamlessly into their systems without modification.

Our replacement encoders are constructed from industrial-grade materials, tested for durability, reliability, and consistent long-term performance. This ensures that operators can maintain uninterrupted production while avoiding unexpected downtime.

FAQ – FG40K-2500G-90G-NG

Q: Are custom configurations available?

A: Yes, we offer tailored options to meet specific mechanical, electrical, or connector requirements.

Q: What is the delivery lead time for non-standard orders?

A: 15 working days is typical, providing fast access to critical components.

In summary, the FG40K-2500G-90G-NG custom replacement is a reliable solution for steel and metallurgy operators, combining precision, durability, and rapid availability. Its non-standard customization and short delivery time help overcome procurement challenges and ensure stable operations.

Technical data

| Parameter | Value |

|---|---|

| Pulse rates | |

| Standard pulse rates | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Special pulse rates | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000, 40000, 50000 (further pulse rates according to customer specification) |

| Connection data | |

| Supply voltage | 12 V … 30 V DC (optional: 5 V DC) For UL and CSA Class 2 supplied |

| No load-current | approx. 50 mA at 24 V |

| Outputs | Current limited, short-circuit proof push-pull line driver with integrated impedance adaptation for 30 to 140 Ω lines |

| Pulse height (HTL) | approx. as supply voltage, output saturation voltage < 0.4 V at Iₗ 30 mA |

| Output current | max. 150 mA at 24 V (observe derating) |

| Internal resistance | 75 Ω bei 24 V |

| Slew rate | 200 V/μs with C_L 100 pF |

| Duty cycle | 1:1 ± 3 % for standard pulse rates 1:1 ± 5 % for special pulse rates up to 25000 pulses |

| Square wave displacement 0°, 90° | 90° ± 3 % for standard pulse rates 90° ± 5 % for special pulse rates up to 25000 pulses |

| Max. frequency | 200 kHz, Higher max. frequency on request |

| Special output voltage 5V (TTL) | |

| Pulse height | 5V, RS422-compatible (TIA/EIA-Standard) |

| Supply voltage | 12 … 30 V DC (optional: 5 V DC) For UL and CSA Class 2 supplied |

| Alternative Connection Data (from image(1)_1.png) | |

| Supply voltage | 5 V … 30 V DC For UL and CSA Class 2 supplied |

| No load-current | Approx. 120 mA at 5 V, approx. 50 mA at 24 V |

| Output signals | 2 sinusoidal signals A and B each with inverted signals Reference pulse with inverted signal Signal amplitude 1 V pp / R_L = 120 Ω Error signal and inverted signal Signal amplitude 5V |

| Resolution | 1024 signal periods |

| Duty cycle | 1 ± 0.1 |

| Phase shift A, B | 90° ± 1° |