8.A128.6832.3112 Multiturn Absolute Encoder Custom Replacement

Custom Replacement Capability

The 8.A128.6832.3112 can be replaced with our custom-designed multiturn absolute encoder, which maintains full mechanical and electrical compatibility with the original unit. Our replacement solutions offer a rapid production cycle of approximately fifteen working days, considerably faster than typical international procurement times. This helps minimize operational downtime and ensures that critical systems continue running efficiently. The unit preserves all key dimensions, shaft interfaces, and signal outputs, providing a seamless transition from the original encoder to the custom replacement.

Product Overview

This encoder provides absolute position feedback over multiple rotations, retaining accuracy even after power interruptions. It features high-resolution measurement in both singleturn and multiturn modes, which is essential for precision automation and motion control applications. Communication interfaces include SSI, Profibus, and CANopen, offering broad compatibility with industrial control systems. The 8.A128.6832.3112 is built with a rugged housing and precision bearings, ensuring reliability under demanding industrial conditions. Its multiturn capability makes it ideal for applications requiring continuous monitoring of multi-revolution motion.

Visual Note

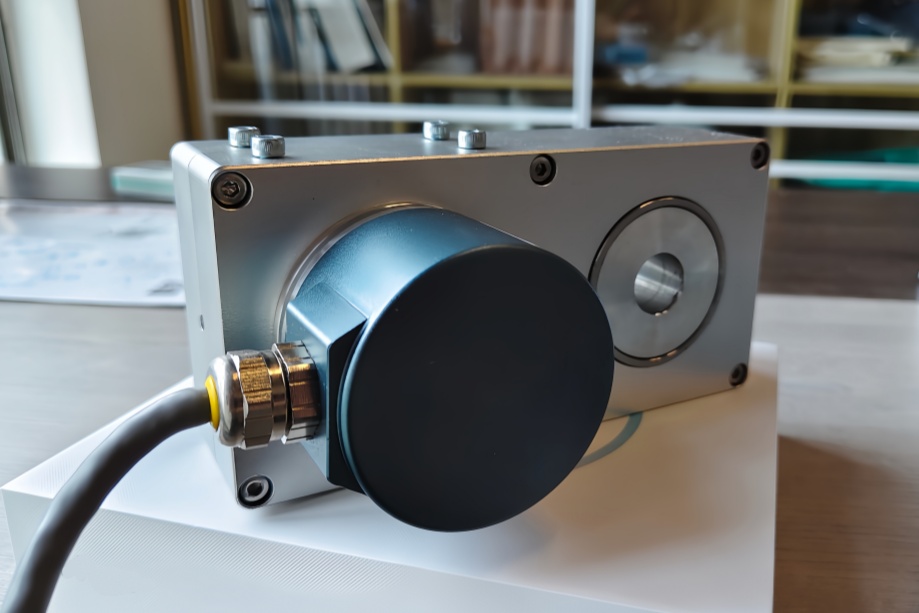

Customized product real photos available.

Industrial Applications

The encoder is commonly used in steel production, cranes, automated conveyors, wind turbines, and robotic systems. It supports precise roller positioning, hoist control, and synchronization of conveyor lines, reducing operational errors. In cranes, it ensures safe and accurate cable handling, while in wind turbines, it monitors blade pitch and nacelle rotation. Robotic and packaging systems rely on the encoder for repeated, high-accuracy operations. Its robust performance under continuous use reduces maintenance frequency and increases overall operational efficiency.

Our Advantage

Our replacement solution offers cost-effective, reliable, and timely alternatives. Customers can customize the electrical interface, resolution, and mechanical design to meet specific operational requirements. With a production lead time of around fifteen working days, our solution minimizes downtime and provides high-precision performance, comparable to the original manufacturer’s unit. The durable construction ensures long-term reliability, making it a practical and dependable choice for demanding industrial environments.