8.A16C.F324.G323 Codificador absoluto multivuelta recambio personalizado

Custom Replacement Capability

The 8.A16C.F324.G323 can be fully replaced with our custom-made encoder solution, which is mechanically and electrically compatible with the original. Our production cycle of approximately fifteen working days enables customers to reduce procurement time and minimize operational downtime. The unit preserves all critical mounting dimensions, shaft interfaces, and signal outputs, ensuring seamless integration into existing industrial systems.

Product Overview

This encoder provides precise absolute position feedback across multiple shaft rotations, maintaining accuracy even after power interruptions. It offers high-resolution measurement in both singleturn and multiturn modes, essential for motion control and precision automation applications. Supported communication interfaces include SSI, Profibus, and CANopen. The encoder is built with a robust housing and high-quality bearings, ensuring long-term durability and reliability in demanding industrial environments. Multiturn functionality allows for continuous monitoring of multi-revolution motion, providing reliable feedback for complex automation systems.

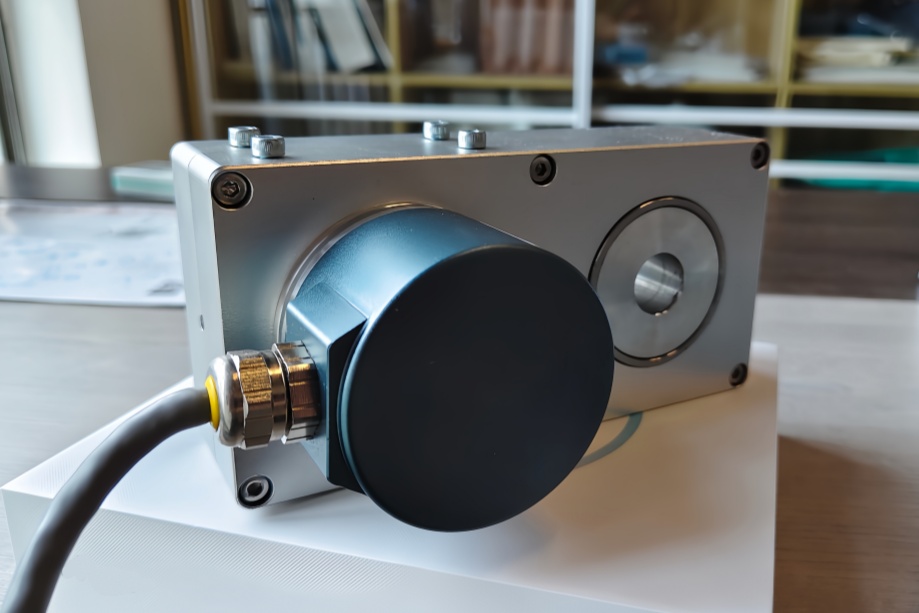

Visual Note

Customized product real photos available.

Industrial Applications

The 8.A16C.F324.G323 is widely used in steel production, cranes, automated conveyors, wind turbines, and robotic systems. In steel plants, it provides precise roller positioning and hoist control. Cranes rely on the encoder for accurate cable handling, and conveyors utilize it to synchronize material movement. Wind turbines employ the encoder for blade pitch and nacelle rotation monitoring. In packaging and robotic systems, it delivers consistent high-resolution feedback for repeated operations. Its reliability reduces maintenance frequency and increases productivity across these industries.

Our Advantage

Our replacement solution is cost-effective and highly reliable. Customers can customize electrical interfaces, resolution, and mechanical features to suit specific application requirements. Production lead times are short, typically around fifteen working days, while robust construction ensures long-term performance. This encoder provides a dependable alternative to original units, maintaining precision and operational efficiency in high-demand industrial environments.