GM401.Z29 Wind Turbine Encoder Custom Replacement Solution

We provide a high-quality customized replacement solution for the GM401.Z29 encoder, designed to match original specifications with a 1:1 non-standard customization process. Our engineering capability ensures that both mechanical structure and electrical characteristics are precisely aligned with the original model, enabling a seamless replacement. Production can be completed within 10–15 working days, allowing us to deliver faster than many traditional suppliers. This efficient manufacturing schedule is particularly valuable for wind energy operators, where timely delivery and rapid replacement directly reduce downtime and maintenance costs. Customers benefit from a reliable supply source, enhanced flexibility, and cost savings, while maintaining full compatibility with the original system.

The GM401.Z29 replacement encoder inherits the advanced design features of the Baumer GM400 series, ensuring exceptional performance in wind turbine applications. It utilizes a multiturn measuring system with SSI interface and an optical sensing method, guaranteeing high-resolution data acquisition and excellent accuracy. The encoder provides up to 14 bits resolution for singleturn readings and 16 bits for multiturn capability, delivering precise positioning even under demanding operating conditions. Mechanical installation is simplified with a clamping flange design, ensuring robust and secure mounting. The product also includes electronic zero-point setting functionality, allowing operators to configure the reference point conveniently during installation. Additional features such as counting direction input and optional incremental outputs further extend its flexibility for integration into existing systems. With its maximum resistance to magnetic fields, the GM401.Z29 encoder ensures stable and reliable operation in challenging environments where electromagnetic interference is common, making it perfectly suited for wind turbines and other industrial energy systems.

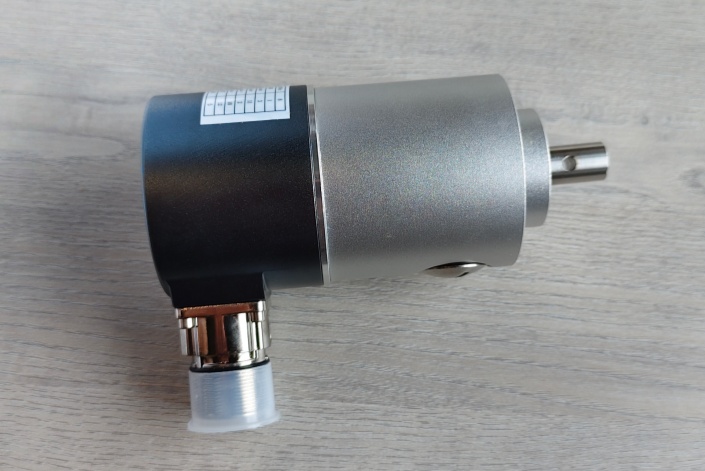

Replacement model real product photo

Technical Data

Electrical Ratings

| Parameter | Values |

|---|---|

| Voltage supply | 10…30 VDC5 VDC ±10 % |

| Reverse polarity protection | Yes (10…30 VDC) / No (5 VDC) |

| Consumption w/o load | ≤50 mA (24 VDC)≤80 mA (5 VDC) |

| Initializing time typ. | 20 ms after power on |

| Interface | SSIIncremental A 90° B (optional) |

| Function | Multiturn |

| Steps per revolution | ≤16384 / 14 bit |

| Number of revolutions | ≤65536 / 16 bit |

| Absolute accuracy | ±0.025° |

| Sensing method | Optical |

| Code | Gray or binary |

| Code sequence | CW/CCW coded by connection |

| Inputs | SSI clock; Control signals UP/DOWN inv. and zero; SSI data outputs RS422 |

| Output stages | Diagnostic: 1024, 2048 pulses + invertedIncremental output: 512, 1024, 2048 push-pull |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-4 |

| Diagnostic function | Self-diagnosis; Multiturn sensing |

| Approval | UL approval / E63076 |

Mechanical Design

| Parameter | Values |

|---|---|

| Size (flange) | ∅58 mm |

| Optional |

|---|

| Stainless steel design |

| Corrosion protection for offshore applications |

| Parameter Category | Values |

|---|---|

| Shaft type | α10 design solid shaft |

| Flange | Clamping flange |

| Protection EN 60529 | IP 54 (without shaft seal)IP 65 (with shaft seal) |

| Operating speed | ≤10000 rpm (mechanical)≤6000 rpm (electric) |

| Angular acceleration | ≤25000 rad/s² (UB = 0 VDC)≤25000 rad/s² (UB = 10…30 VDC, 5 VDC) |

| Starting torque | ≤0.015 Nm (+25 °C, IP 54)≤0.03 Nm (+25 °C, IP 65) |

| Rotor moment of inertia | 20 g·cm² |

| Admitted shaft load | ≤20 N axial≤40 N radial |

| Material | Housing: aluminiumFlange: aluminium |

| Operating temperature | -25…+85 °C-40…+85 °C (optional) |

| Relative humidity | 95 % non-condensing |

| Resistance | EN 60068-2-6Vibration ≤0.75 mm - 10 - 58 Hz, 10 g - 58 - 2000 HzEN 60068-2-27Shock 200 g, 6 ms |

| Weight approx. | 400 g |

| Connection | Connector M23, 12-pinConnector M12, 8-pinCable 1 m |