For the 565035 AC58/0010EK.42SBB, we deliver a custom-engineered replacement solution designed to ensure full 1:1 compatibility with the original encoder’s performance, dimensions, and SSI output. Non-standard customization options are available, including specialized connectors, reinforced shafts, and protective coatings tailored for harsh industrial environments. Each unit undergoes stringent quality control, functional testing, and compatibility verification, guaranteeing seamless integration with existing systems. With a production cycle of 10–15 working days, this solution helps customers minimize procurement delays and maintain uninterrupted operation in critical industrial applications. Optional enhancements, such as IP-rated enclosures, vibration-resistant components, and extended temperature range materials, can be provided to meet the most demanding operational conditions.

The AC58 SSI Absolute Encoder is widely used in industrial automation, robotic systems, CNC machining, automated warehouses, material handling equipment, energy generation, and packaging machinery. Known for high precision, robust performance, and reliable SSI communication, it ensures stable real-time feedback in multi-axis control systems and synchronized industrial operations. Its durable housing and high-quality bearings allow it to function effectively under vibration, temperature extremes, dust, and electromagnetic interference. By adopting our custom replacement solution, enterprises can maintain high system accuracy, minimize downtime, and continue to rely on the proven performance of the original AC58 SSI Absolute Encoder.

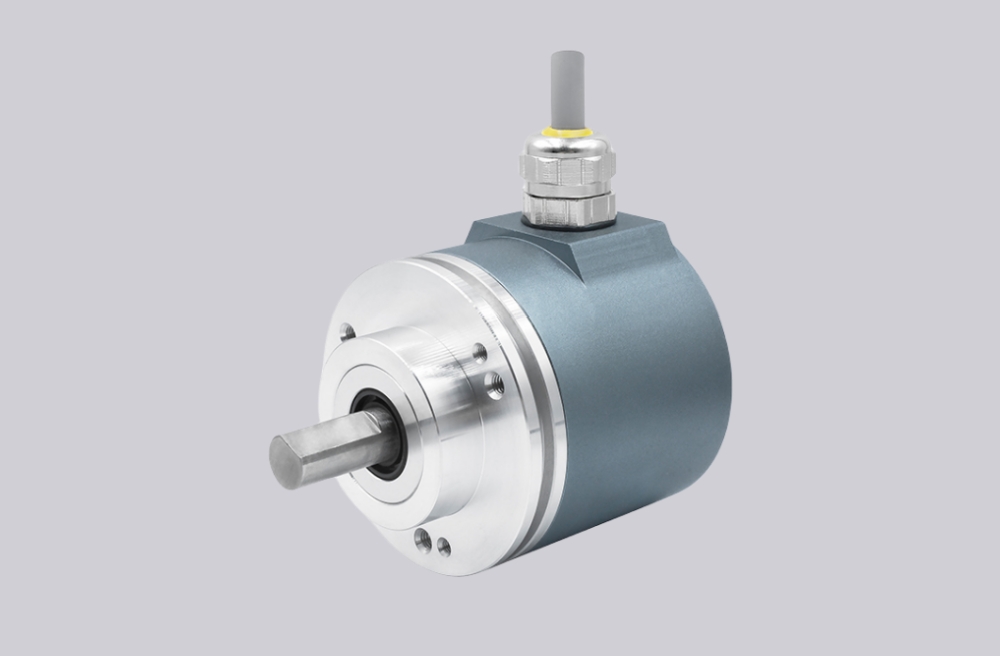

Replacement solution product image available.

Ficha técnica

| Parámetro | Detalles |

|---|---|

| Diámetro de la carcasa | 58 mm |

| Diámetro del eje | 6 mm / 10 mm (eje macizo)10 mm / 12 mm (eje de cubo) |

| Alcance (Montaje de la carcasa) | Brida sincronizada, Brida de sujeción, Amarre, Brida cuadrada |

| Clase de protección | Entrada del eje (EN 60529): IP64 o IP67Carcasa (EN 60529): IP64 o IP67 |

| Carga axial / radial del eje | 40 N / 60 N |

| Juego axial del eje de montaje (eje de cubo) | ± 1,5 mm |

| Salto radial del eje de acoplamiento (eje de cubo) | ± 0,2 mm |

| Velocidad máxima | máx. 10.000 rpm (continuo), máx. 12.000 rpm (corto plazo) |

| Par de arranque típico ² | ≤ 0,01 Nm |

| Momento de inercia | c.a. 3,8 × 10-⁶ kg-m² |

| Resistencia a las vibraciones (DIN EN 60068-2-6) | 100 m/s² (10... 2000 Hz) |

| Resistencia a los golpes (DIN EN 60068-2-27) | 1000 m/s² (6 ms) |

| Temperatura de funcionamiento | -40 ℃... + 100 ℃ |

| Temperatura de almacenamiento ¹ | -25 ℃... + 85 ℃ |

| Peso | aprox. 260 g (ST) / 310 g (MT) |

| Conexión | Cable, axial o radialConector M23 (Conin), 12 polos, axial o radialConector M12, 8 polos, axial o radial |

Especificaciones eléctricas

| Parámetro | Detalles |

|---|---|

| Tensión de alimentación | ± 10% CC 5 V o CC 10 - 30 V |

| Corriente sin carga típ. | 100 mA (ST), 150 mA (MT) |

| Resolución monovuelta | 10 - 17 BitGray Excess: 360, incrementos de 720 |

| Resolución multivuelta | 12 Bit |

| Código de salida | Binario, Gris |