En FG4KK-16384G-90G-NG is a high-resolution heavy-duty incremental encoder engineered for critical applications in the steel and metallurgy industry. With an impressive 16,384 pulses per revolution, it provides ultra-precise feedback required for controlling rolling mills, continuous casting systems, large industrial drives, and high-speed automation processes. Its robust construction allows it to endure the harsh conditions often encountered in steel plants, including high temperatures, heavy vibrations, and continuous operation under full load.

Due to its status as a legacy model, sourcing the original FG4KK-16384G-90G-NG has become increasingly difficult. To address this challenge, we have developed a custom replacement encoder that replicates the original’s specifications exactly. This includes mechanical dimensions, electrical interfaces, signal output characteristics, and rotational accuracy, ensuring a direct drop-in solution without requiring modifications to existing equipment or control systems.

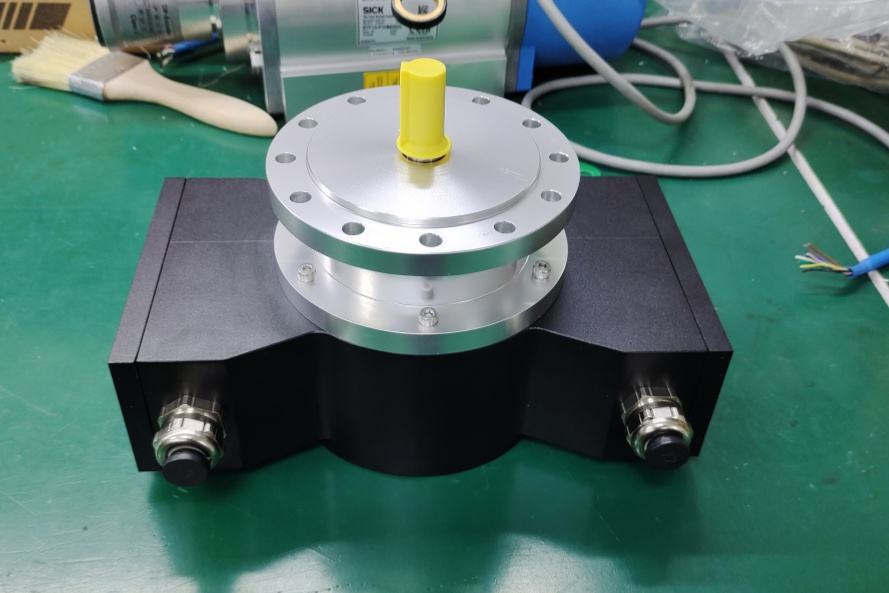

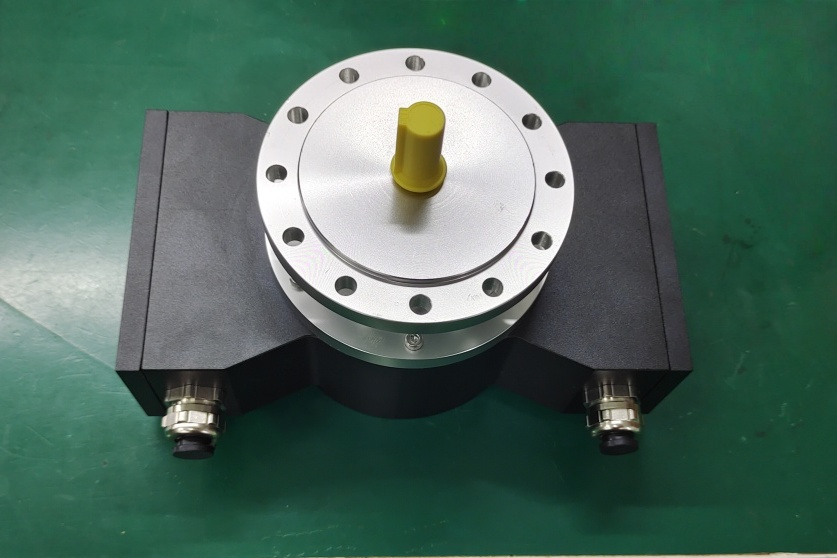

Solución alternativa Imagen del producto

Aplicaciones:

- Rolling mills for real-time speed and position monitoring

- Continuous casting systems for precise alignment and process control

- Heavy-duty industrial drives in metallurgical and steel production

- Automation and process control systems requiring high-resolution feedback

Expert’s note: The FG4KK-16384G-90G-NG replacement excels in precision and reliability, critical for high-value steel manufacturing operations. Its heavy-duty design ensures continuous operation with minimal maintenance, while our custom service allows clients to tailor encoders for unique operational requirements, securing long-term equipment uptime and consistent process quality.

To address supply shortages and tight delivery schedules, we offer custom non-standard replacement services for the FG4KK-16384G-90G-NG. This service allows clients to request units tailored to their specific requirements, ensuring compatibility and reliability. Our typical lead time for non-standard orders is 15 working days, providing a fast and efficient solution for operators facing difficulties sourcing legacy encoders. By leveraging this service, steel and metallurgy plants can maintain production continuity and reduce downtime.

Ficha técnica

Pulsaciones

| Categoría | Valor |

|---|---|

| Frecuencias de pulso estándar | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Pulsaciones especiales | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000(otras frecuencias de pulso según especificación del cliente) |

Datos de conexión

| Parámetro | Detalles |

|---|---|

| Tensión de alimentación | 12 V ... 30 V CCPara UL y CSA Clase 2 suministrado |

| Corriente en vacío | aprox. 50 mA a 24 V |

| Salidas | Conductor de línea push-pull limitado en corriente y a prueba de cortocircuitos con adaptación de impedancia integrada para líneas de 30 a 140 Ω. |

| Altura del pulso (HTL) | aprox. como tensión de alimentación, tensión de saturación de salida < 0,4 V a Iₗ 30 mA |

| Corriente de salida | máx. 150 mA a 24 V (observar reducción de potencia) |

| Resistencia interna | 75 Ω a 24 V |

| Velocidad de giro | 200 V / μs con Cₗ 100 pF |

| Ciclo de trabajo | 1:1 ± 3 % para frecuencias de impulsos estándar1:1 ± 5 % para frecuencias de impulsos especiales hasta 25000 impulsos |

| Desplazamiento de onda cuadrada 0°, 90 | 90° ± 3 % para frecuencias de impulsos estándar90° ± 5 % para frecuencias de impulsos especiales hasta 25000 impulsos |

| Frecuencia máxima | 200 kHz, Frecuencia máx. superior bajo pedido |

Tensión de salida especial 5V (TTL)

| Parámetro | Detalles |

|---|---|

| Altura del pulso | 5 V, compatible con RS422 (TIA/EIA - Estándar) |

| Tensión de alimentación | 12 ... 30 V CC (opcional: 5 V CC)Para UL y CSA Clase 2 suministrado |