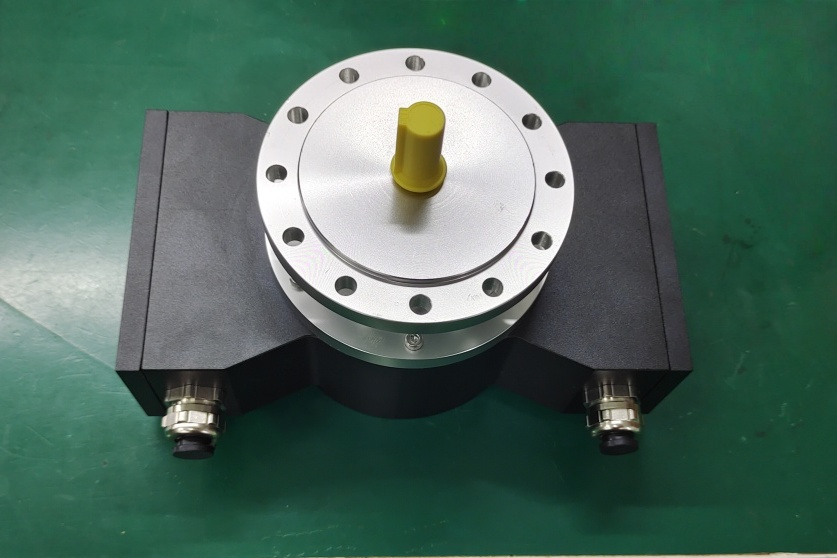

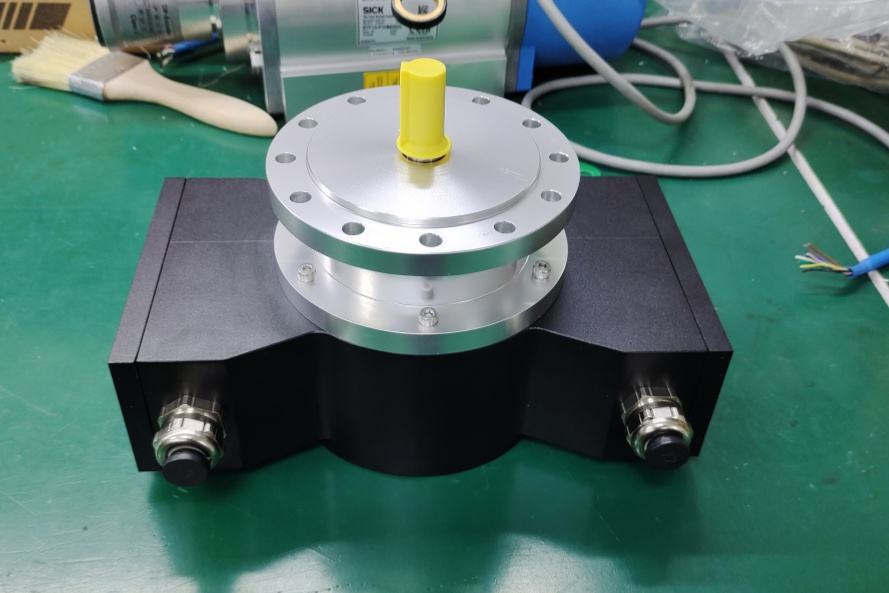

The FG40KK-2500G-90G-NG is a heavy-duty incremental encoder widely used in steel rolling mills, metallurgical drives, and other demanding applications where reliable feedback is essential. With 2500 pulses per revolution, it strikes an excellent balance between precision and resilience.

This encoder has earned its reputation for withstanding harsh conditions—from elevated temperatures to continuous vibration and exposure to dust or oil. Its strong mechanical structure makes it a dependable choice for operators who cannot afford interruptions in steel production.

Recognizing the challenges in sourcing such encoders quickly, we have developed a custom replacement product with identical specifications. Our solution integrates seamlessly into existing equipment, eliminating the need for adjustments while restoring operational efficiency.

Our encoders are manufactured with an emphasis on durability, long service life, and consistent output signals, ensuring that they deliver dependable performance over extended use in critical applications. This reliability is particularly important in steel plants, where downtime is costly.

We also provide customizable options, allowing our customers to order encoders with unique specifications suited to their environment. Whether it is mechanical adaptation or specific output requirements, our team ensures each replacement is tailored for optimal fit and performance.

To further support our clients, we offer non-standard customization with a delivery period of 15 working days. This significantly reduces waiting time, helping steel industry operators address procurement bottlenecks and keep their production lines running smoothly.

Technical data

| Parameter | Value |

|---|---|

| Pulse rates | |

| Standard pulse rates | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Special pulse rates | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000, 40000, 50000 (further pulse rates according to customer specification) |

| Connection data | |

| Supply voltage | 12 V … 30 V DC (optional: 5 V DC) For UL and CSA Class 2 supplied |

| No load-current | approx. 50 mA at 24 V |

| Outputs | Current limited, short-circuit proof push-pull line driver with integrated impedance adaptation for 30 to 140 Ω lines |

| Pulse height (HTL) | approx. as supply voltage, output saturation voltage < 0.4 V at Iₗ 30 mA |

| Output current | max. 150 mA at 24 V (observe derating) |

| Internal resistance | 75 Ω bei 24 V |

| Slew rate | 200 V/μs with C_L 100 pF |

| Duty cycle | 1:1 ± 3 % for standard pulse rates 1:1 ± 5 % for special pulse rates up to 25000 pulses |

| Square wave displacement 0°, 90° | 90° ± 3 % for standard pulse rates 90° ± 5 % for special pulse rates up to 25000 pulses |

| Max. frequency | 200 kHz, Higher max. frequency on request |

| Special output voltage 5V (TTL) | |

| Pulse height | 5V, RS422-compatible (TIA/EIA-Standard) |

| Supply voltage | 12 … 30 V DC (optional: 5 V DC) For UL and CSA Class 2 supplied |

| Alternative Connection Data (from image(1)_1.png) | |

| Supply voltage | 5 V … 30 V DC For UL and CSA Class 2 supplied |

| No load-current | Approx. 120 mA at 5 V, approx. 50 mA at 24 V |

| Output signals | 2 sinusoidal signals A and B each with inverted signals Reference pulse with inverted signal Signal amplitude 1 V pp / R_L = 120 Ω Error signal and inverted signal Signal amplitude 5V |

| Resolution | 1024 signal periods |

| Duty cycle | 1 ± 0.1 |

| Phase shift A, B | 90° ± 1° |