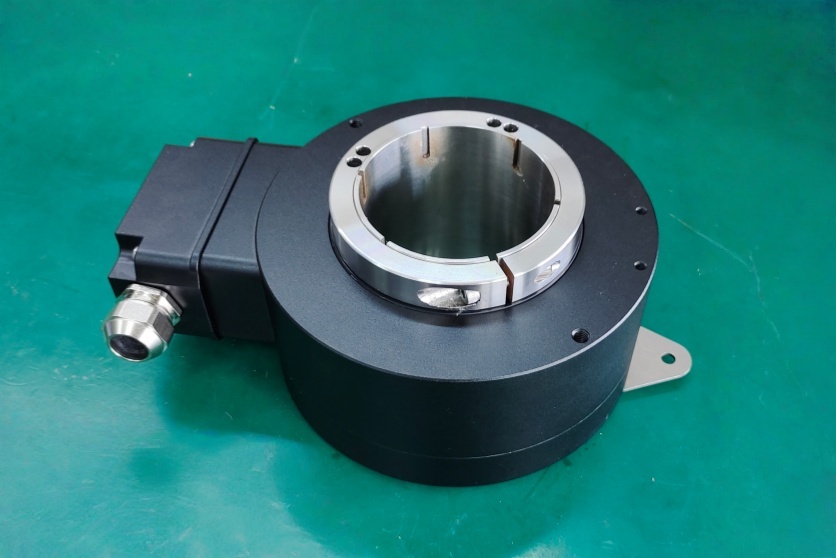

HOG161 DN 1024 I 38H7 Heavy Duty Encoder Custom Replacement Available

Product Review:

The HOG161 DN 1024 I 38H7 is a high-performance incremental encoder specifically designed for demanding industrial tasks. With a 38H7 hollow shaft, this model offers compact installation and ensures reliable shaft coupling without slippage. It delivers 1024 pulses per revolution, providing precise incremental signals needed for speed monitoring and position feedback in automation systems. Thanks to its reinforced bearings, durable housing, and resistance to vibration, the encoder maintains long-term stability even under harsh load cycles. Industries such as metallurgy, heavy cranes, and bulk material handling benefit from its robust and accurate feedback capability.

Custom Replacement:

We supply customized non-standard encoder replacements compatible with the HOG161 DN 1024 I 38H7. Our alternatives can be tailored in shaft size, mounting configuration, and output interface to meet your exact system requirements. For applications needing special adjustments, we can provide extended cable lengths, unique connector types, or additional sealing for dust and moisture protection. Unlike long lead times from standard suppliers, our production cycle is just 15 working days, ensuring you receive fast and reliable delivery. Choosing our tailored replacement solutions helps you minimize downtime and maintain stable operation without compromise.

Technical data - electrical ratings

| Voltage supply | 9..30 VDC 5VDC+5% 9...26 VDC |

|---|---|

| Consumption w/o load | ≤100mA |

| Pulses per revolution | 250....2500 |

| Phase shift | 90°+20° |

| Duty cycle | 40...60% |

| Reference signal | Zero pulse,width 90° |

| Sensing method | Optical |

| Output frequency | S120 kHz |

| Output signals | K1,K2,KO+inverted |

| Output stages | HTL TTL/RS422 |

| Interference immunity | EN61000-6-2 |

| Emitted interference | EN61000-6-3 |

| Approval | CE UL approval/E217823 |

Technical data - mechanical design

| Protection EN 60529 | IP54 |

|---|---|

| Operating speed | S6000 rpm (mechanical) |

| Operating torque typ. | 15 Ncm |

| Rotor moment of inertia | 26.3 kgcm2(48) 13.5 kgcm2(75) |

| Material | Housing: aluminium alloy Shaft: stainless steel |

| Operating temperature | -40..+85℃ |

| Resistance | IEC 60068-2-6 Vibration 10g, 10-2000 Hz IEC 60068-2-27 Shock 100 g,6ms |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions C4 according to ISO12944-2 |

| Explosion protection | I13G Ex ec IIC T4 Gc (gas) I1 3 D Extc II T10C Dc(dust) (only with option ATEX) |

| Connection | Terminal box 2x terminal box (with option M) |

| Weight approx. | 4.5kg (048) 3.2kg(075) 3.6 kg (o75 with option M) |