In demanding industries like oil and gas, equipment reliability is not just an advantage—it’s a necessity. The M6C-4S1HX51ZTZ00 heavy-duty encoder has earned a reputation for its rugged performance, precise motion feedback, and strong resistance to harsh environments. Users in petroleum applications particularly value its ability to maintain stability under extreme temperatures, vibration, and continuous operation, making it a trusted solution for mission-critical systems.

Replacement Solution for M6C-4S1HX51ZTZ00 Encoder

We specialize in providing replacement solutions for the M6C-4S1HX51ZTZ00 Avtron M6 incremental encoder. Our alternative products are engineered using customized non-standard manufacturing techniques, while ensuring a 1:1 match with the original specifications. This guarantees smooth integration with existing setups, without requiring design changes or additional adjustments.

Key Highlights:

- Fully compatible replacement for the M6C-4S1HX51ZTZ00 Avtron M6 encoder

- Exact replication of mechanical and electrical parameters

- Designed to endure oilfield environments and heavy-duty cycles

- Helps resolve supply chain challenges and long procurement lead times

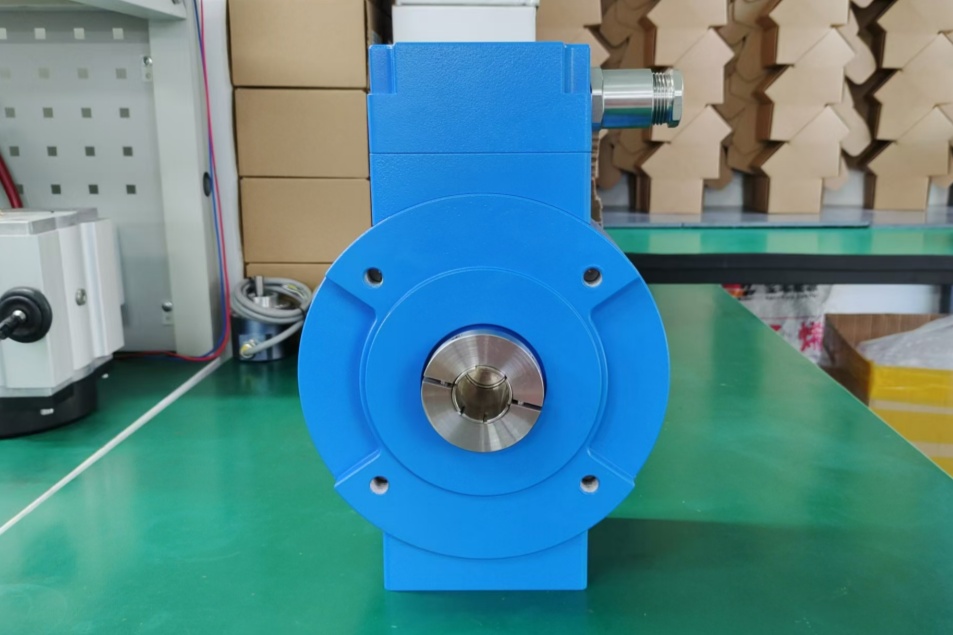

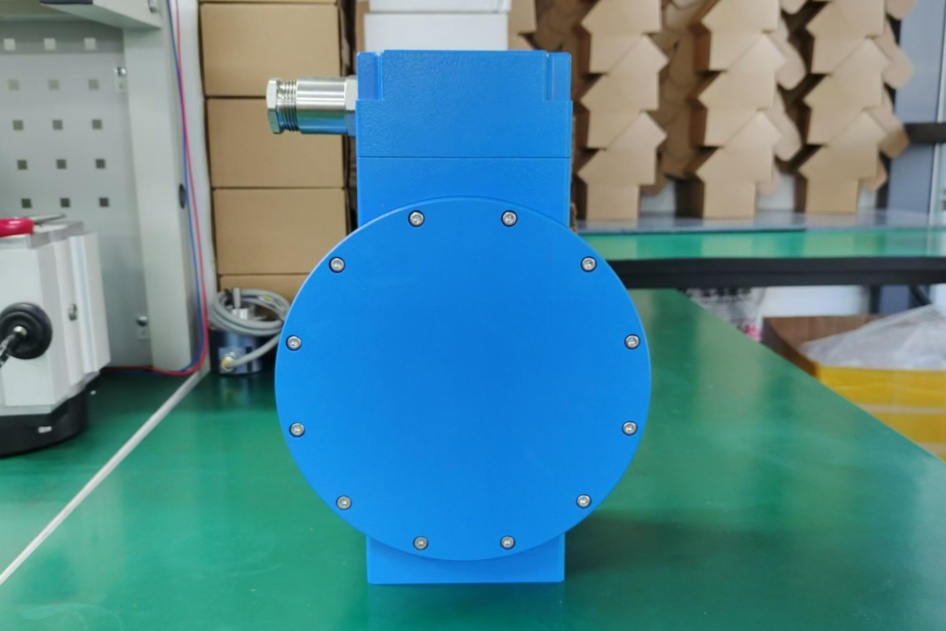

Real product photos provided for customer assurance

By adopting our replacement encoder, companies in the petroleum industry can reduce downtime, maintain precision in control systems, and secure a cost-effective alternative to the original unit—all without compromising performance.

Introduction

Avtron M6C explosion protected ATEX and IECEx rated severe mill duty rotary encoders are designed for direct mounting on motor or load shafts, from 1" to 1 1/8" [25-30mm].

The M6C is an updated model which directly replaces the M6 encoder, and M6C adds IECEx certification. No barrier or isolator is required-mount M6C directly in any ATEX or IECEx Zone 1 application.

Why take a chance with weak optical encoders on your drilling rig? The M6C features Avtron Encoders' rugged magnetic sensor and solid metal rotor technology. Our shatterproof, moisture proof systems ensure your application has maximum uptime. The hollow shaft (tethered) models offer direct mounting on shafts from 1" to 1 1/8", without flanges, reducers, couplings, or other hardware. No rework is needed; just mount the encoder directly on the shaft, and secure the tether arm. The heavy duty bearings withstand runout and vibration that destroy lesser encoders.

M6C also includes a complete wiring protection system--it can survive all types of wiring errors and drive signals down the longest cables.

For more information on keeping your rotary encoders working in oil and gas applications, visit our oil and gas blog.

We believe explosion protected encoders should also be ready to withstand the rough drilling environment. Try the M6C today!

Parameters

Operating Power: Volts: 5-24 VDC; Current: 120mA, no load

Output Format: A, /A, B, /B; Optional Marker Z, /Z

Frequency Range: 0 to 250 kHz @ 6 V & 1 meter cable

PPR: 240-1200

Speed: 5000 RPM Max. Std.

Temperature: 80°C to -40°C (-40°C optional, -20°C standard)

Chemical: Polyurethane enamel paint protects against salt spray, mild acids, and bases

Enclosure Rating: IP66

Explosion Protection:

ATEX 0539 II 2 G Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

IECEx Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

Weight: 18 lbs. / 8kg.