For the 565035 AC58/0010EK.42SBB, we deliver a custom-engineered replacement solution designed to ensure full 1:1 compatibility with the original encoder’s performance, dimensions, and SSI output. Non-standard customization options are available, including specialized connectors, reinforced shafts, and protective coatings tailored for harsh industrial environments. Each unit undergoes stringent quality control, functional testing, and compatibility verification, guaranteeing seamless integration with existing systems. With a production cycle of 10–15 working days, this solution helps customers minimize procurement delays and maintain uninterrupted operation in critical industrial applications. Optional enhancements, such as IP-rated enclosures, vibration-resistant components, and extended temperature range materials, can be provided to meet the most demanding operational conditions.

The AC58 SSI Absolute Encoder is widely used in industrial automation, robotic systems, CNC machining, automated warehouses, material handling equipment, energy generation, and packaging machinery. Known for high precision, robust performance, and reliable SSI communication, it ensures stable real-time feedback in multi-axis control systems and synchronized industrial operations. Its durable housing and high-quality bearings allow it to function effectively under vibration, temperature extremes, dust, and electromagnetic interference. By adopting our custom replacement solution, enterprises can maintain high system accuracy, minimize downtime, and continue to rely on the proven performance of the original AC58 SSI Absolute Encoder.

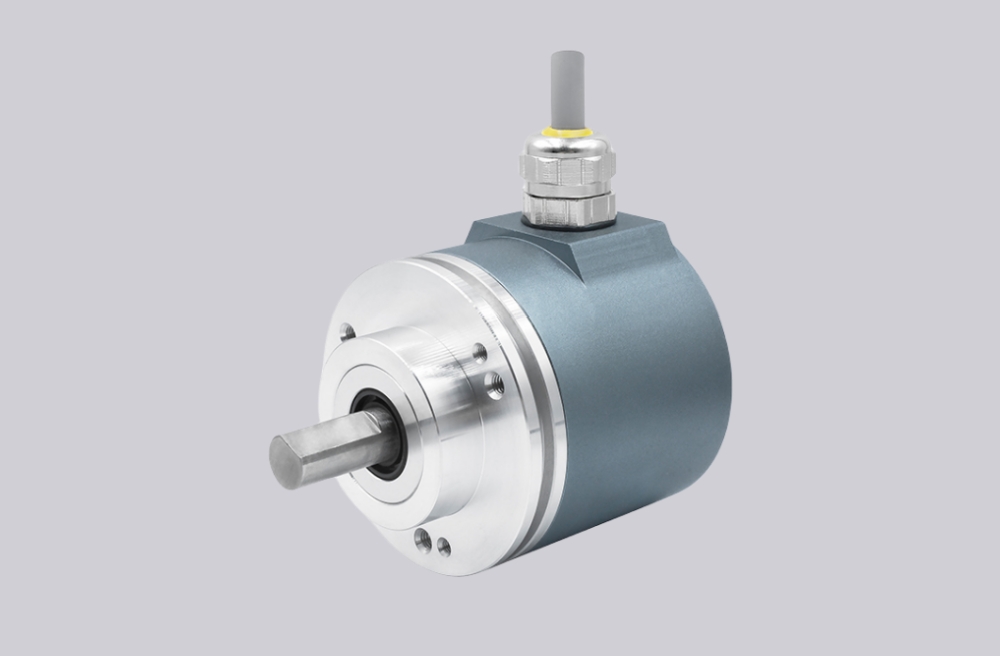

Replacement solution product image available.

Lembar Data Teknis

| Parameter | Detail |

|---|---|

| Diameter rumah | 58 mm |

| Diameter poros | 6 mm / 10 mm (Poros padat) 10 mm / 12 mm (Poros hub) |

| Jangkauan (Pemasangan housing) | Flensa sinkronisasi, Flensa penjepit, Tambat, Flensa persegi |

| Kelas perlindungan | Input poros (EN 60529): IP64 atau IP67Housing (EN 60529): IP64 atau IP67 |

| Beban poros aksial / radial | 40 N / 60 N |

| Pemutaran ujung aksial poros pemasangan (poros gandar) | ± 1,5 mm |

| Lari radial dari poros kawin (hubshaft) | ± 0,2 mm |

| Maks. kecepatan | maks. 10.000 rpm (kontinu), maks. 12.000 rpm (jangka pendek) |

| Tipe torsi awal. ² | ≤ 0,01 Nm |

| Momen inersia | c.a. 3,8 × 10-⁶ kg-m² |

| Ketahanan terhadap getaran (DIN EN 60068-2-6) | 100 m/s² (10 ... 2000 Hz) |

| Ketahanan terhadap guncangan (DIN EN 60068-2-27) | 1000 m/s² (6 ms) |

| Suhu pengoperasian | -40 ℃... + 100 ℃ |

| Suhu penyimpanan ¹ | -25 ℃... + 85 ℃ |

| Berat | sekitar 260 g (ST) / 310 g (MT) |

| Koneksi | Kabel, konektor M23 (Conin), 12 kutub, konektor M12 aksial atau radial, 8 kutub, aksial atau radial |

Spesifikasi Listrik

| Parameter | Detail |

|---|---|

| Tegangan suplai | ± 10% DC 5 V atau DC 10 - 30 V |

| Jenis arus tanpa beban saat ini. | 100 mA (ST), 150 mA (MT) |

| Resolusi satu putaran | 10 - 17 Kelebihan BitGray: Peningkatan 360, 720 |

| Resolusi multiturn | 12 Bit |

| Kode keluaran | Biner, Abu-abu |