The ATM90-PTG13x11 hollow shaft Profibus encoder replacement solution is positioned to help customers bridge supply shortages while retaining system accuracy and reliability. With a guaranteed production time of only 10 working days, our solution provides quick access to compatible encoders and ensures delivery schedules align with demanding project timelines. This reduces the risk of prolonged equipment downtime, a common issue faced by industries relying on difficult-to-source encoder models.

Our replacement products have been deployed successfully across regions including South America, Southeast Asia, Russia, and Indonesia. They are known for robust mechanical construction, strong shock and vibration tolerance, and reliable Profibus connectivity. For encoders that are no longer available or extremely difficult to procure, we specialize in designing customized alternatives. These can be configured to match the original technical parameters precisely, enabling seamless integration and preventing costly retrofitting or redesign. By offering flexible non-standard solutions, we help customers maintain operational efficiency under complex conditions.

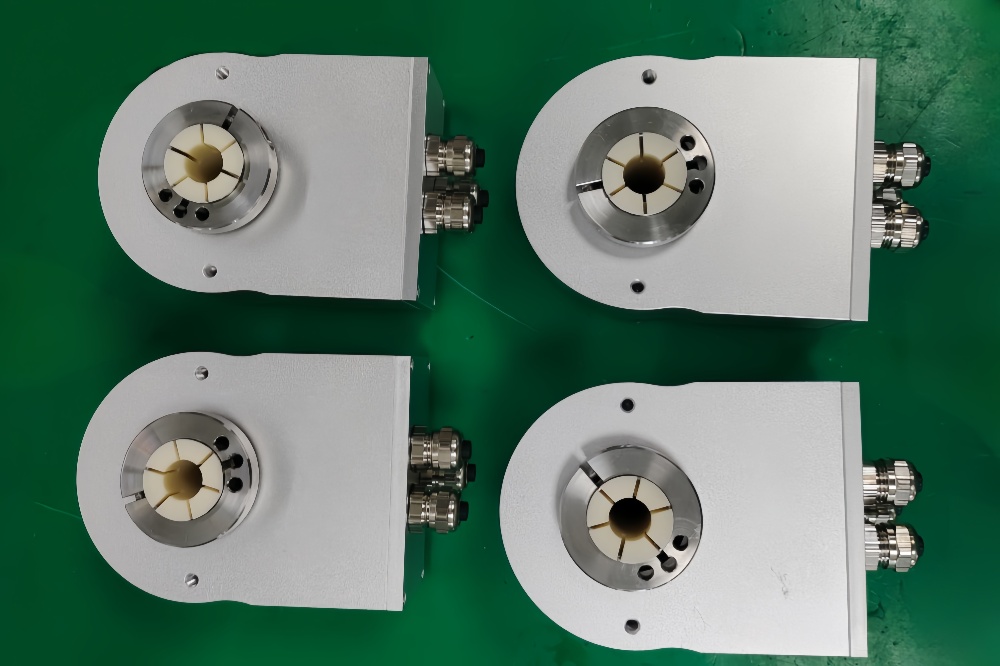

Replacement solution image display.

Lembar Data Teknis

Performance

| Parameter | Detail |

|---|---|

| Number of steps per revolution (max. resolution) | 8,192 (13 bit) |

| Number of revolutions | 2,048 (11 bit) |

| Max. resolution (number of steps per revolution × number of revolutions) | 13 bit × 11 bit (8,192 × 2,048) |

| Measuring step | 0.043°* |

| Error limits G | ± 0.25° *¹) |

| Repeatability standard deviation σᵣ | 0.1° *²) |

Interfaces

| Parameter | Detail |

|---|---|

| Communication interface | PROFIBUS DP |

| Communication interface detail | DPV0 |

| Data protocol | Profile for encoders (07hex) - Class 2 |

| Address setting | 0 ... 127, DIP switches or protocol |

| Data transmission rate (baud rate) | 9.6 kBaud ... 12 MBaud, automatic detection |

| Initialization time | 1.250 ms 1) |

| Position forming time | 0.25 ms |

| Status information | LED green (operation), LED red (bus activity) |

| Bus termination | DIP switch 2) |

| Set (electronic adjustment) | Via PRESET push button or protocol |

Electronics

| Parameter | Detail |

|---|---|

| Connection type | Bus adapter, 3x, M14, 7-pin, radial |

| Tegangan suplai | 10 ... 32 V |

| Power consumption | ≤ 2 W (without load) |

Mechanics

| Parameter | Detail |

|---|---|

| Mechanical design | Through hollow shaft |

| Diameter poros | 12mm |

| Berat | 0.6 kg 1) |

| Shaft material | Stainless steel |

| Flange material | Aluminum |

| Start up torque | 0.5 N·m (+20 °C) |

| Operating torque | 0.4 N·m (+20 °C) |

| Operating speed | ≤ 3,000 min⁻¹ 2) |

| Moment of inertia of the rotor | 153 g·cm² |

| Bearing lifetime | 3.6 × 10⁹ revolutions |

| Angular acceleration | ≤ 600,000 rad/s² |

Ambient data

| Parameter | Detail |

|---|---|

| EMC | According to EN 61000 - 6 - 2 and EN 61000 - 6 - 3 |

| Enclosure rating | IP65, with shaft seal (IEC 60529) 1) |

| Permissible relative humidity | 98 % |

| Operating temperature range | -20 °C ... +80 °C |

| Storage temperature range | -40 °C ... +100 °C, without package |

| Resistance to shocks | 6 g, 20 ms (EN 60068 - 2 - 27) |

| Resistance to vibration | 20 g, 10 Hz ... 2,000 Hz (EN 60068 - 2 - 6) |