We provide a fully customized replacement solution for the SWF10B-FK-01 draw wire displacement sensor, designed with precise 1:1 application parameters and identical installation dimensions. Utilizing a non-standard production process, we can significantly shorten delivery times, typically completing production within 7–10 working days. This approach ensures rapid delivery, seamless integration into existing systems, and full mechanical and electrical compatibility without modification.

The replacement sensor is built with a high-precision stainless-steel wire mechanism and durable spring return system, providing stable and accurate linear displacement measurement. It is suitable for automation, hydraulic control, and industrial lifting systems where reliability and repeatability are essential. The design ensures resistance to environmental stress and long operational life. This replacement solution has been successfully implemented in Southeast Asia, Indonesia, South America, the Middle East, and Russia, proving its precision, durability, and adaptability across diverse industrial applications.

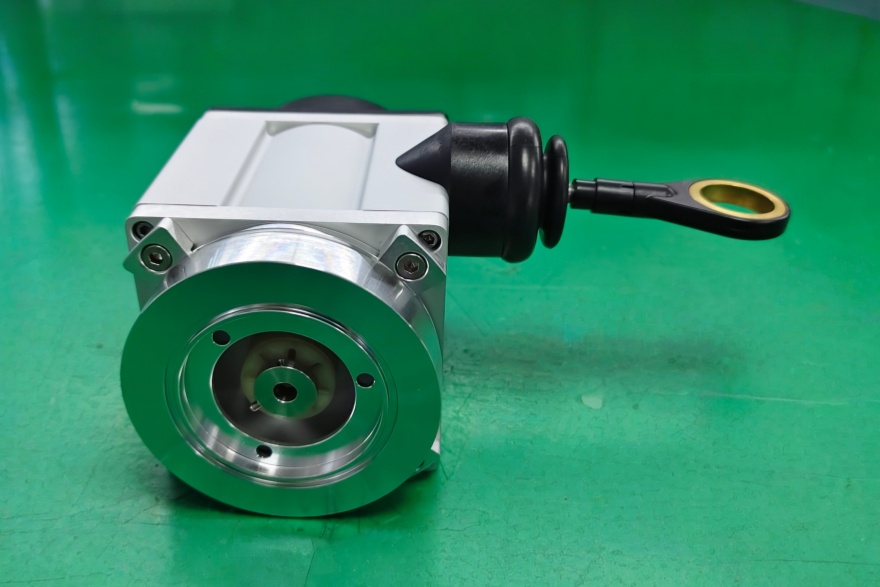

Replacement solution image.

Technical Data

| Parameter | Value |

|---|---|

| Measuring ranges | 5, 10, 15, 20, 25, 30 meters |

| Drum circumference | 333 mm (nom.) |

| Permissible speed | ref. to table page 2 |

| Permissible cable acceleration | ref. to table page 2 |

| Force required to draw out the cable (start / end) | max. 15 N / max. 30 N |

| Cable material and diameters | Highly flexible stranded wire (Stainless steel 1.4401)5 to 25 m: 1.3 mm diameter30 m: 0.80 mm diameter |

| Life expectancy for cable and spring | ≥10×10⁶ cable strokes |

| Housing material | Anodized aluminum |

| Spring housing | Plastic |

| Working and storage temperature range | -20℃ to +70℃; optional -30℃ |

| Protection grades | Housing: IP65Cable entry: IP54 |

| Mass | ref. to table page 2 |