The AMS40K-1312 SSI absolute encoder can be provided as a 1:1 customized replacement solution, with a standard production lead time of 10 working days. Our replacement model is designed to precisely match the original encoder’s mechanical dimensions, shaft configuration, and SSI communication interface, ensuring direct electrical and mechanical compatibility. This plug-and-play solution allows users to install the replacement encoder effortlessly without modifying system wiring or control parameters.

From a technical standpoint, the AMS40K-1312 encoder delivers high-resolution absolute position feedback and stable SSI signal transmission, making it suitable for heavy-duty industrial applications such as steel processing, paper manufacturing, and large-scale automation systems. Its rugged construction and precision engineering ensure exceptional performance and reliability, even under conditions of high vibration and temperature variation. Our replacement encoders have been successfully deployed in South America, Southeast Asia, the Middle East, Indonesia, and Russia, where they are recognized for their durability and long-term stability.

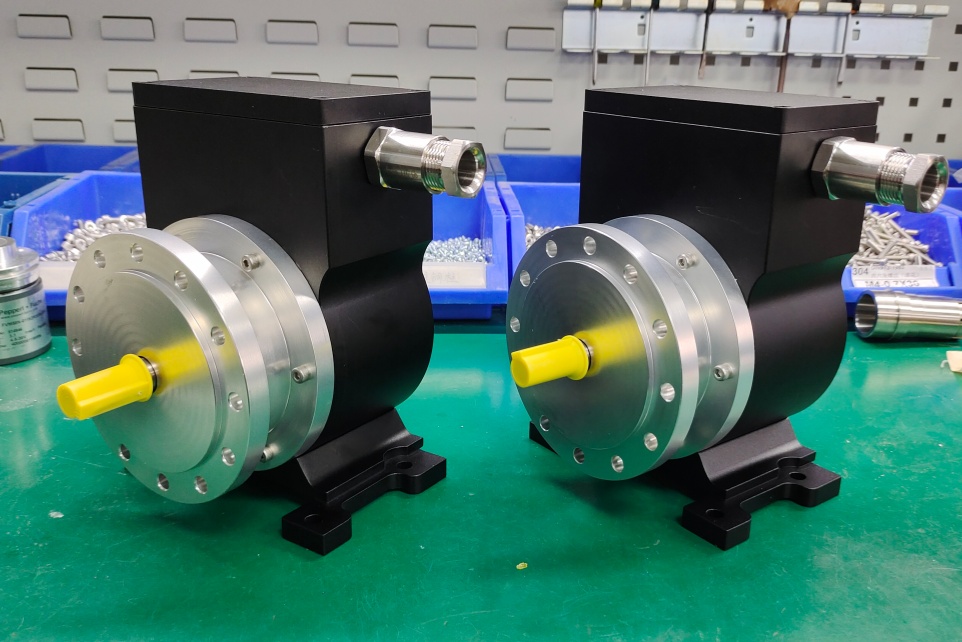

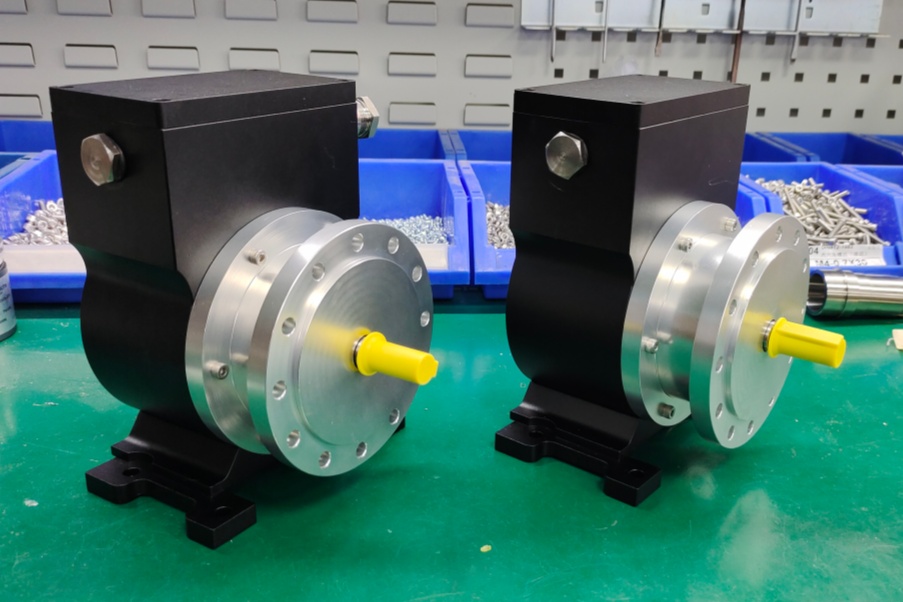

Gambar solusi pengganti

Data teknis

1. Data koneksi

| Parameter | Detail |

|---|---|

| Tegangan suplai | 12... 30 V DC |

| Konsumsi daya tanpa beban | sekitar 1 W |

| Resolusi satu putaran | Maks. 16 bit (65536 langkah per putaran) lihat pelat tipe |

| Resolusi multiturn | 12 bit (4096 putaran) lihat pelat tipe |

| Format data | SSI, kode biner/abu-abu (lihat pelat jenis) |

2. Antarmuka SSI

| Parameter | Detail |

|---|---|

| Masukan jam | RS 422 / 5V |

| Arus masukan | 5 mA |

| Frekuensi jam | 80kHz... 1 MHz |

| Laju jam/transmisi | 25 / 13 (multiturn / singleturn) |

| Waktu habis SSI | > 30 μs (tanpa pengulangan data) < 20 μs (dengan pengulangan data) |

| Antarmuka data | RS 422 / 5V |

3. Sinyal kontrol

| Parameter | Detail |

|---|---|

| V/IR, Z (input) | 5... 30V / 5mA |

| Status (keluaran) | HTL |

| Kisaran suhu | -25°C... +85°C; Untuk UL dan CSA -25°C... +70°C |

4. Tingkat perlindungan menurut DIN EN 60529

| Tingkat perlindungan | Penyegelan | Mech. kecepatan yang diizinkan | Momen inersia rotor | Torsi yang memisahkan diri |

|---|---|---|---|---|

| IP 66 | dengan segel Labirin | ≤6000 rpm | sekitar 580 gcm² | sekitar 6 Nm |

| IP 66 / IP 67 | dengan segel poros aksial | ≤4000 rpm | sekitar 510 gcm² | sekitar 8 Nm |

| IP 66 / IP 67 | Dengan segel poros radial (untuk aplikasi khusus, misalnya area basah di rolling mill) | ≤3000 rpm | sekitar 510 gcm² | sekitar 9 Nm |

5. Ketahanan getaran, ketahanan guncangan, dan beban poros

| Parameter | Standar | Nilai |

|---|---|---|

| Ketahanan terhadap getaran | DIN EN 60068-2-6 / IEC 68-2-6 (10 ... 2000 Hz) | 20 g (=200 m/s²) |

| Tahan guncangan | DIN EN 60068-2-27 / IEC 68-2-27 (6 ms) | 150 g (=1500 m/s²) |

| Maks. beban poros encoder | - | Fₐ, maks (aksial) = 100 N; Fᵣ, maks (radial) = 120 N |

6. Dimensi poros

| Parameter | Detail |

|---|---|

| Dimensi poros | 11j6 x 30 mm (standar); 14j6 x 30 mm (opsional) |

7. Berat

| Parameter | Jenis | Detail |

|---|---|---|

| Berat | Tipe K (tipe konstruksi B5) | sekitar 3,1 kg |