8.A148.M134.3412 Substituição personalizada do codificador absoluto multivoltas

Custom Replacement Capability

The 8.A148.M134.3412 is a multiturn absolute encoder that can be fully replaced with our custom-made alternative solution. We provide tailor-made encoders that are mechanically and electrically compatible with the original model, ensuring that installation and interface are seamless. Our replacement product maintains the same mounting dimensions, shaft compatibility, and signal output as the original encoder. More importantly, we offer a fast production cycle of about fifteen working days, significantly shorter than typical international lead times. This allows customers to reduce waiting periods, optimize maintenance schedules, and minimize downtime in critical production environments. Choosing our custom replacement ensures technical compatibility and timely delivery, helping businesses maintain smooth operations even under tight schedules.

Product Overview

The 8.A148.M134.3412 is designed as a high-precision multiturn absolute encoder, providing absolute position feedback over multiple rotations of a shaft. Unlike incremental encoders, it retains exact position information even after power interruptions, eliminating the need for re-homing. This encoder typically delivers high-resolution measurements in both singleturn and multiturn modes, making it suitable for precision automation systems. It supports multiple industrial communication interfaces such as SSI, Profibus, or CANopen, depending on the customer’s requirements. Mechanically, it is built with a robust housing and strong bearing structure, capable of withstanding continuous industrial operation. Its multiturn capability is particularly beneficial for long travel paths or applications that require consistent position tracking across multiple rotations.

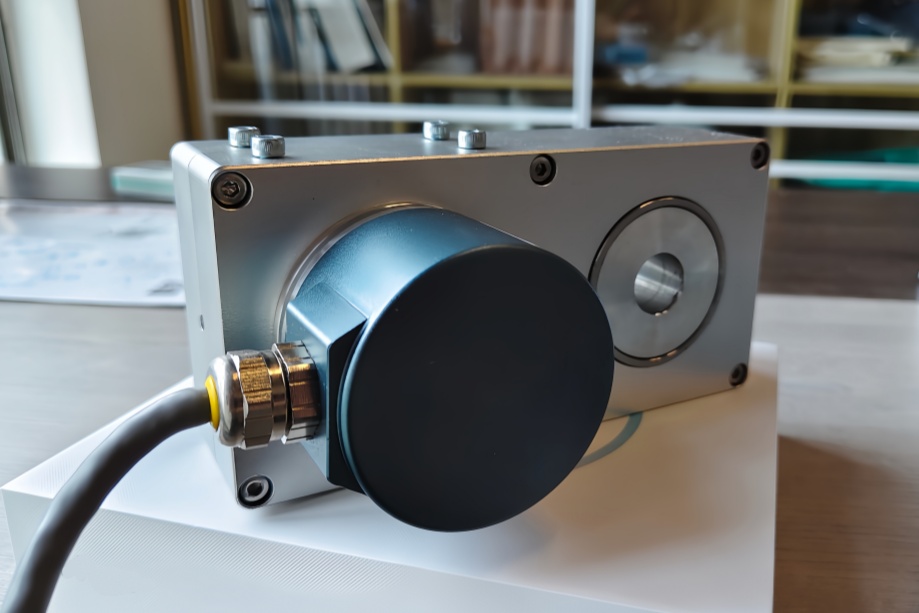

Visual Note

Customized product real photos available.

Industrial Applications

The 8.A148.M134.3412 finds applications across several demanding industrial environments. In steel and metallurgical plants, it is used for roller positioning, hoisting systems, and continuous casting equipment where precise shaft positioning is crucial. In crane and hoist systems, it ensures accurate winding and unwinding of cables on drums, preventing overloads and enhancing operational safety. Automated conveyor systems utilize this encoder to synchronize speed, direction, and position, minimizing material handling errors. In renewable energy, such as wind turbines, the encoder monitors nacelle rotation and blade pitch, optimizing performance under varying wind conditions. It is also used in packaging and robotic systems, delivering consistent accuracy over repeated cycles. Across all these sectors, the encoder provides reliable absolute positioning, contributing to efficiency and reduced maintenance risk.

Our Advantage

Our replacement solution offers multiple competitive advantages. Lead times are significantly shorter than the original manufacturer, typically around fifteen working days. Customization options allow adjustment of electrical interface, resolution, and mechanical design to meet specific application needs. The solution is cost-effective without compromising performance, helping businesses reduce procurement costs while maintaining system reliability. Its robust design and flexibility make it a dependable choice for high-demand industries. By choosing our custom replacement, customers gain a reliable, timely, and technically compatible solution that supports operational efficiency and reduces downtime.