For the 565024 AC58/0017EK.42SGH, we provide a comprehensive custom replacement solution engineered to deliver exact 1:1 compatibility with the original model. Each encoder is carefully designed to replicate the electrical specifications, mechanical dimensions, mounting interfaces, and SSI signal outputs, ensuring effortless system integration. To address specialized needs, we also provide non-standard adaptations such as customized brackets, reinforced connectors, or protective coatings for challenging industrial environments. Every unit is subjected to stringent quality inspections, full functional testing, and compatibility verification, guaranteeing dependable performance in real-world applications. With a production cycle of 10–15 working days, customers gain faster procurement, reduced downtime, and a reliable encoder solution ready for immediate deployment. In addition, optional upgrades—including enhanced shaft strength, optimized bearing assemblies, and IP-rated housings—are available to meet demanding operational requirements across sectors such as energy, manufacturing, and automated logistics.

The AC58 SSI Absolute Encoder is widely used in industrial automation, robotic arms, CNC machinery, material handling systems, conveyor networks, renewable energy applications, and process control systems. Its high-resolution and robust construction ensure precise and reliable position feedback even under harsh industrial conditions, including vibration, temperature extremes, dust, and electromagnetic interference. The SSI interface enables noise-resistant, real-time serial communication, critical for multi-axis motion control and synchronized industrial operations. Engineers value this encoder for its consistency, durability, and ability to maintain precise operation across a wide range of applications. By adopting our custom replacement solution, enterprises can maintain operational continuity, improve maintenance efficiency, and overcome sourcing challenges associated with legacy SSI Absolute Encoders.

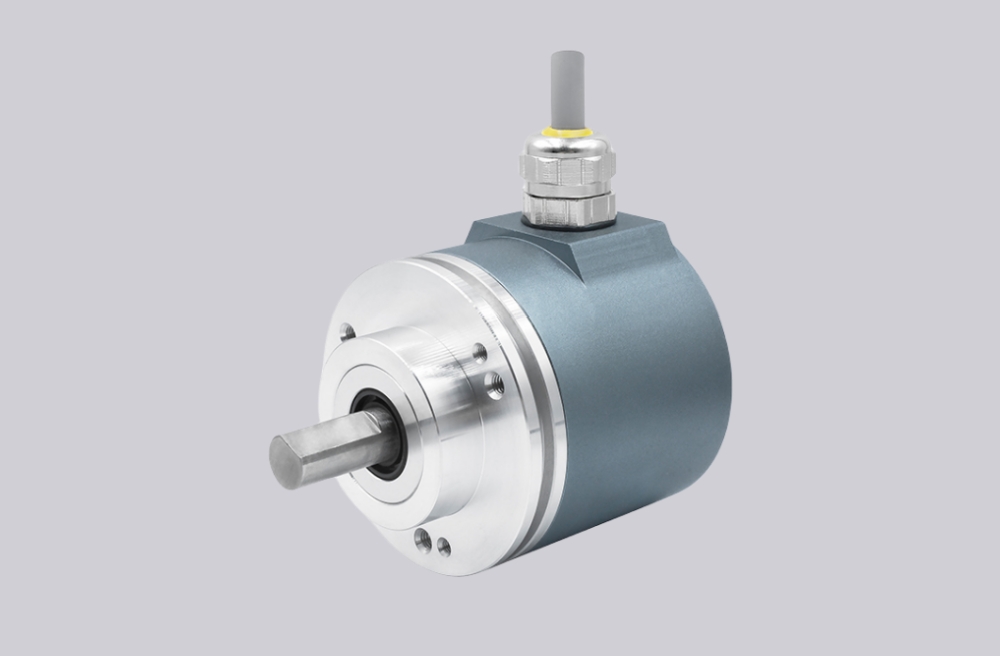

Replacement solution product image available.

Technical Datasheet

| Parameter | Details |

|---|---|

| Housing diameter | 58 mm |

| Shaft diameter | 6 mm / 10 mm (Solid shaft)10 mm / 12 mm (Hub shaft) |

| Range (Mounting of housing) | Synchro flange, Clamping flange, Tether, Square flange |

| Protection class | Shaft input (EN 60529): IP64 or IP67Housing (EN 60529): IP64 or IP67 |

| Shaft load axial / radial | 40 N / 60 N |

| Axial endplay of mounting shaft (hubshaft) | ± 1.5 mm |

| Radial runout of mating shaft (hubshaft) | ± 0.2 mm |

| Max. speed | max. 10,000 rpm (continuous), max. 12,000 rpm (short term) |

| Starting torque typ. ² | ≤ 0.01 Nm |

| Moment of inertia | c.a. 3.8 × 10⁻⁶ kg·m² |

| Vibration resistance (DIN EN 60068-2-6) | 100 m/s² (10... 2000 Hz) |

| Shock resistance (DIN EN 60068-2-27) | 1000 m/s² (6 ms) |

| Operating temperature | -40 ℃... + 100 ℃ |

| Storage temperature ¹ | -25 ℃... + 85 ℃ |

| Weight | approx. 260 g (ST) / 310 g (MT) |

| Connection | Cable, axial or radialM23 connector (Conin), 12 pole, axial or radialM12 connector, 8 pole, axial or radial |

Electrical Specifications

| Parameter | Details |

|---|---|

| Supply voltage | ± 10% DC 5 V or DC 10 - 30 V |

| Current w/o load typ. | 100 mA (ST), 150 mA (MT) |

| Resolution singleturn | 10 - 17 BitGray Excess: 360, 720 increments |

| Resolution multiturn | 12 Bit |

| Output code | Binary, Gray |