The FG4KK-5000G-90G-NG is a robust heavy-duty incremental encoder widely used across steel plants, rolling mills, metallurgical equipment, and other heavy machinery. With a 5,000-pulse resolution, it provides accurate speed monitoring, motor feedback, and position control, ensuring smooth operation of machinery under high-load, high-temperature, and high-vibration conditions. Its heavy-duty design allows for long service life and resistance to harsh industrial environments, making it ideal for critical automation and process control systems.

As this model has become hard-to-source, we developed a fully compatible replacement encoder that duplicates the original’s key specifications. This ensures a direct, drop-in solution, eliminating the need for extensive system modifications or downtime. The replacement unit offers reliable incremental output, robust mechanical integrity, and full compatibility with existing industrial systems, providing confidence in operations where precision and durability are paramount.

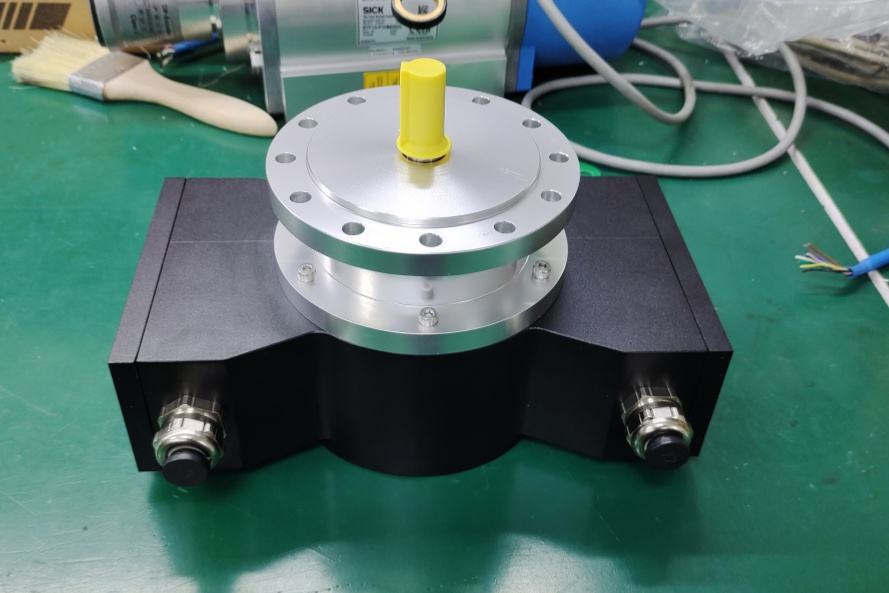

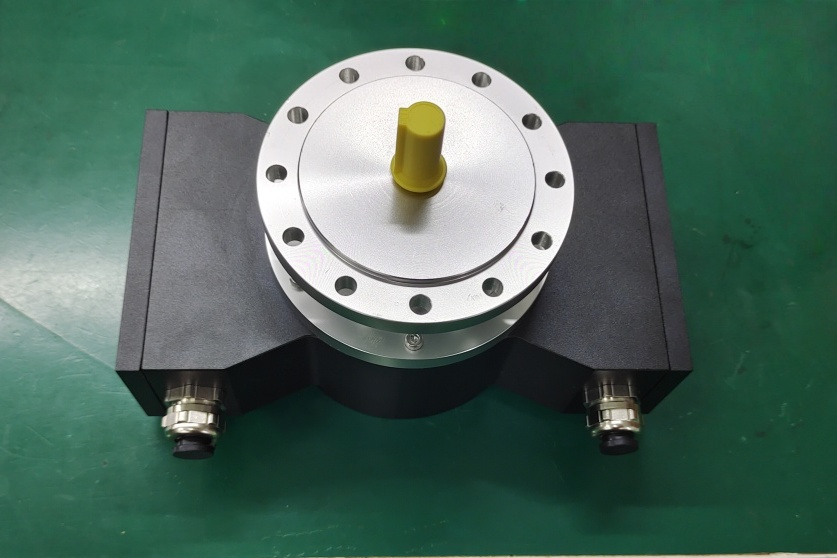

Alternative Solution Product Image

Applications:

- Steel plant automation for motor and conveyor control

- Rolling mills requiring precise synchronization of heavy machinery

- Metallurgical automation systems with continuous heavy-load operations

- Industrial equipment requiring incremental feedback for motion control

Expert’s note: For the steel and metallurgy sector, operational downtime is extremely costly. The FG4KK-5000G-90G-NG replacement encoder provides a dependable solution for maintaining uptime, delivering consistent performance under high stress conditions. Its design reflects a perfect balance of precision, durability, and adaptability, making it an ideal choice for replacing legacy equipment while ensuring long-term reliability.

To help clients overcome procurement challenges and long lead times, we accept custom non-standard orders for the FG4KK-5000G-90G-NG. This enables operators to receive fully compatible replacement encoders tailored to their systems. With a standard delivery time of 15 working days, our solution significantly shortens waiting periods for hard-to-source encoders, ensuring steel plants and heavy machinery maintain uninterrupted operations.

Technical Datasheet

Pulse rates

| Category | Value |

|---|---|

| Standard pulse rates | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Special pulse rates | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000(further pulse rates according to customers specification) |

Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12 V … 30 V DCFor UL and CSA Class 2 supplied |

| No load-current | approx. 50 mA at 24 V |

| Outputs | Current limited, short-circuit proof push-pull line driver with integrated impedance adaptation for 30 to 140 Ω lines. |

| Pulse height (HTL) | approx. as supply voltage, output saturation voltage < 0.4 V at Iₗ 30 mA |

| Output current | max. 150 mA at 24 V (observe derating) |

| Internal resistance | 75 Ω bei 24 V |

| Slew rate | 200 V / μs with Cₗ 100 pF |

| Duty cycle | 1:1 ± 3 % for standard pulse rates1:1 ± 5 % for special pulse rates up to 25000 pulses |

| Square wave displacement 0°, 90° | 90° ± 3 % for standard pulse rates90° ± 5 % for special pulse rates up to 25000 pulses |

| Max. frequency | 200 kHz, Higher max. frequency on request |

Special output voltage 5V (TTL)

| Parameter | Details |

|---|---|

| Pulse height | 5V, RS422-compatible (TIA/EIA - Standard) |

| Supply voltage | 12 … 30 V DC (optional: 5 V DC)For UL and CSA Class 2 supplied |