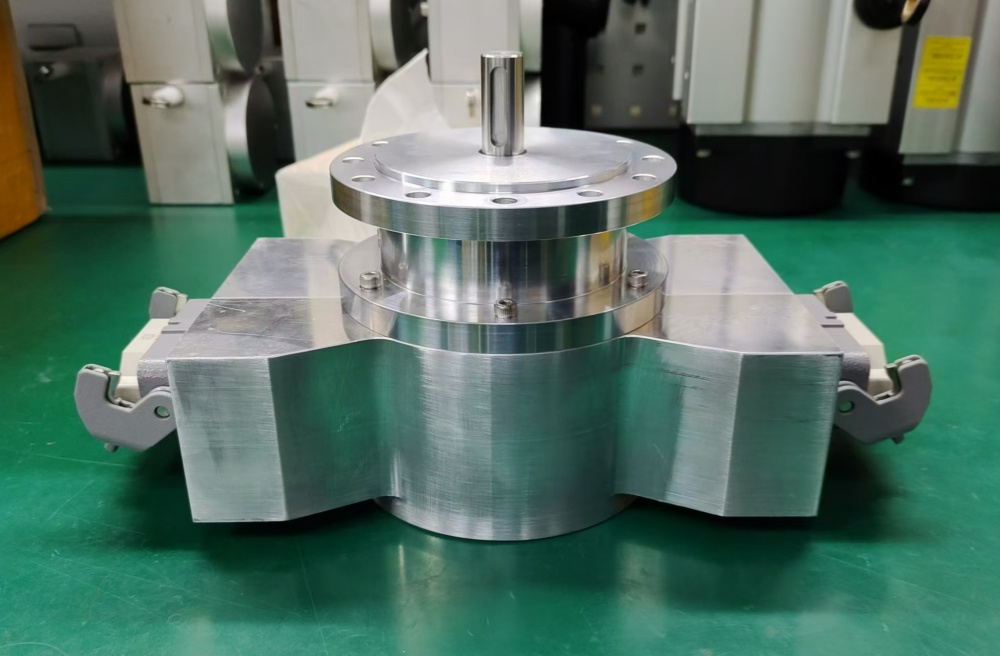

O FG4SS-1200G-90G-NG is a classic incremental encoder that has been serving the industrial automation and heavy-duty machinery sector for more than two decades. Originally released around 2001, this encoder earned a reputation for exceptional reliability and long-term performance. Over the years, it has been widely used in steel mills, rolling lines, and other heavy industrial processes, delivering precise motion control and consistent feedback under harsh operating conditions. Its longevity is a testament to the high-quality engineering and robustness of its design.

Despite its enduring reliability, recent years have seen growing inquiries for alternative solutions. The primary reason is that sourcing the original FG4SS-1200G-90G-NG has become increasingly challenging. As many plants continue to operate with legacy equipment, operators are seeking options that maintain system compatibility without compromising performance. For such legacy encoders, finding a suitable replacement is critical to avoid costly downtime and ensure uninterrupted production.

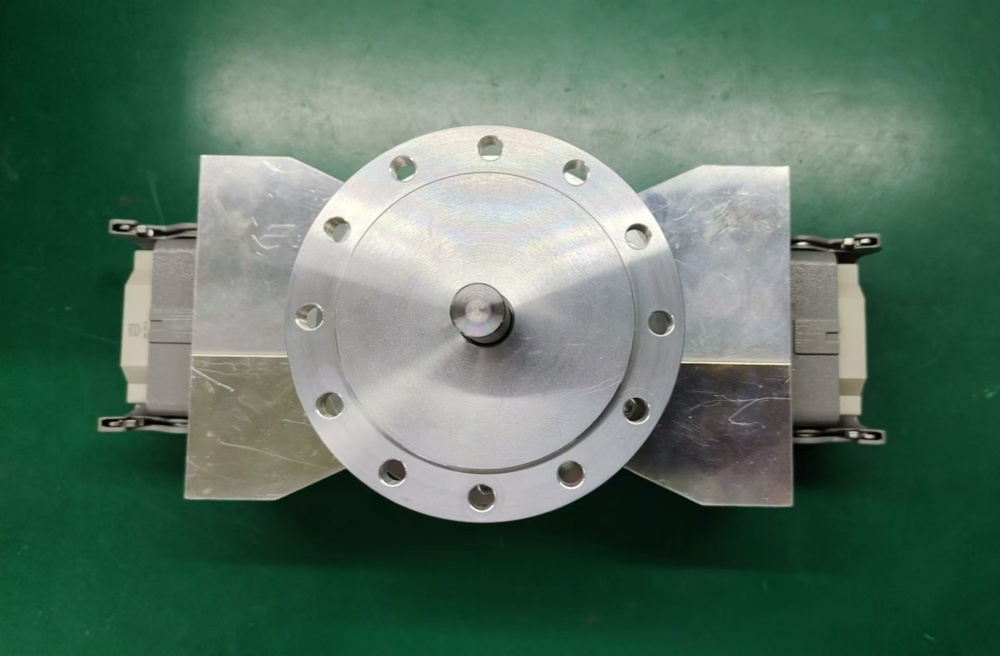

When considering alternatives, there are key technical factors to address. First, the shaft diameter, which comes in either 11mm or 14mm, is crucial. Unlike modern encoders where shaft dimensions are often indicated in the model number, this information cannot be easily confirmed from a visual inspection alone. Accurate shaft measurement is essential to ensure mechanical compatibility with existing machinery.

Another critical aspect is the plug connection and wiring configuration. Pin arrangements can vary, and using incorrect wiring could lead to failure or damage. The most reliable approach is to send the original encoder for inspection, so that pin definitions and electrical specifications can be carefully determined. For the FG4SS-1200G-90G-NG, our team has already mapped the wiring method and verified pin functions, ensuring that any custom replacement can integrate seamlessly.

While basic testing confirms compatibility, additional verification is recommended, especially when dealing with units from different production years. Variations over time may exist in tolerances or connector designs, making it important to ensure the replacement matches the original specifications precisely. This is particularly vital in steel industry applications, where heavy-duty operation demands precise control and signal reliability.

If you encounter a non-functional FG4SS-1200G-90G-NG and cannot procure the original, we provide custom alternative solutions tailored to your needs. Our replacements are engineered to replicate the original encoder’s mechanical and electrical performance, allowing plants to maintain operational continuity without having to redesign their systems. For legacy machinery still in operation, our solutions offer a practical way to preserve “original match” functionality while resolving procurement challenges.

To support industrial operators further, we publish alternative solution details on our website as long as there is ongoing demand. Our goal is to help as many operators as possible overcome the difficulties of sourcing outdated encoders. Additionally, we offer non-standard customization services, typically with a 15 working day lead time, allowing users to quickly receive a replacement and avoid extended production downtime.

In summary, the FG4SS-1200G-90G-NG remains a cornerstone encoder in heavy-duty applications, but the difficulty of purchasing legacy models makes alternatives increasingly important. By offering custom replacement options, verified wiring configurations, and non-standard customization with rapid delivery, we help steel and heavy industry operators maintain reliable operations and uninterrupted productivity, even when dealing with legacy equipment.