8.A12A.68C2.C212 Многооборотный абсолютный энкодер Пользовательская замена

Custom Replacement Capability

The 8.A12A.68C2.C212 can be replaced with our tailor-made multiturn absolute encoder, which matches the original unit in size, shaft interface, and signal output. Customers benefit from our approximately fifteen-working-day production cycle, which is much shorter than standard lead times. This ensures minimal disruption to operations and rapid system recovery. Our custom replacement solution guarantees precise mechanical and electrical compatibility, providing confidence to engineers and maintenance teams. Choosing our solution allows companies to secure an immediate alternative without the usual procurement delays associated with international sourcing, ensuring continuity in industrial processes.

Product Overview

As a multiturn absolute encoder, the 8.A12A.68C2.C212 provides accurate positional feedback over multiple rotations. It delivers high-resolution singleturn and multiturn measurement, essential for precise motion control and positioning applications. The encoder supports communication interfaces such as SSI, CANopen, and Profibus, enabling integration into a variety of industrial control systems. Its solid housing and durable bearings make it capable of withstanding harsh operating environments and long-term usage. The encoder’s design ensures reliability and repeatable accuracy, making it suitable for critical automation processes, long travel applications, and systems that require continuous position monitoring.

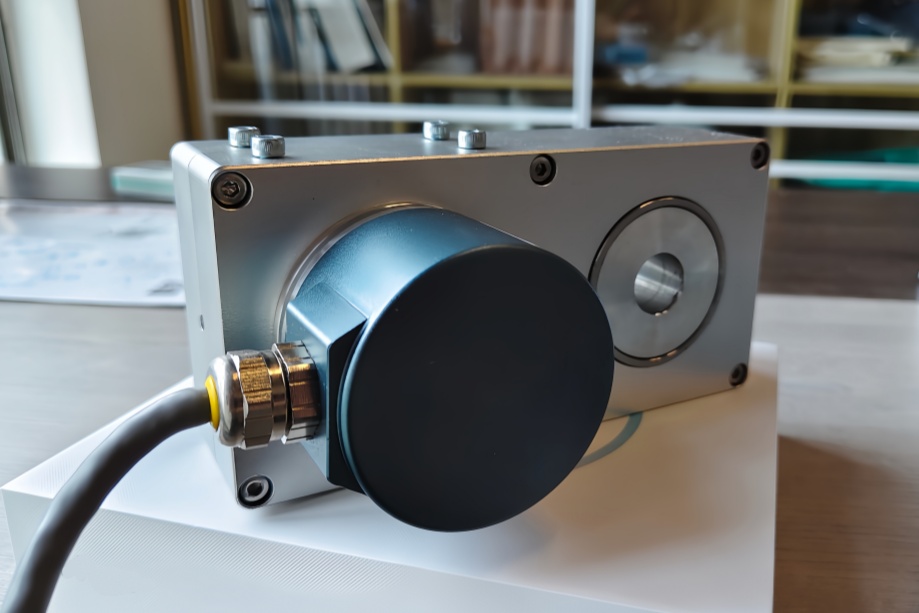

Visual Note

Customized product real photos available.

Industrial Applications

This encoder finds applications in industries such as metallurgy, automation, and energy. In steel manufacturing, it is used for roll alignment and hoist positioning, ensuring precision in heavy machinery. In crane systems, the encoder manages cable winding and drum rotation, reducing safety risks. Automated production lines rely on it for precise material handling and synchronization. In renewable energy systems like wind turbines, it monitors blade pitch and nacelle rotation to maintain optimal performance. Additionally, packaging and robotic automation systems benefit from the encoder’s high-resolution feedback for repetitive and accurate motion control. Its reliability under continuous operation reduces downtime and increases overall system efficiency.

Our Advantage

Our custom replacement offers a cost-effective and reliable alternative. Production lead times are significantly shorter, and customization options cover electrical interface, resolution, and mechanical design. Customers gain a solution that reduces operational risks, ensures system compatibility, and maintains high accuracy. The robust design and adaptability make it ideal for demanding industrial environments, providing a dependable option for companies looking to replace original encoders without compromise.