For companies struggling to obtain the M6C-5S8HX51-W003 encoder, we provide a reliable non-standard customized replacement service. Unlike products stocked in large volumes, our approach focuses on tailored production that ensures exact mechanical fit and matching electrical performance. This strategy allows us to offer flexible solutions that directly address customer requirements without depending on existing inventory. Typically, our production cycle is about 15 working days, which enables us to deliver compatible products within a short timeframe. By doing so, we help minimize equipment downtime, reduce procurement risks, and ensure that critical operations can continue without interruption. Our service is particularly valuable for industries where encoder supply shortages can directly impact productivity and system safety.

The M6C encoder series has long been recognized for its robust performance in heavy-duty applications. One of the most important uses of this model is in winch systems within oil and gas drilling operations, where reliable feedback on rotational speed and shaft position is critical to lifting and lowering heavy loads safely. These working conditions involve strong vibration, mechanical impact, and exposure to dust, oil, and harsh outdoor environments. An encoder designed for such applications must combine precision with exceptional durability, and the M6C family has established itself as a dependable choice. By offering compatible replacement solutions for the M6C-5S8HX51-W003, we support industries such as drilling, mining, steel manufacturing, and material handling, ensuring stable operation, safe lifting control, and consistent process reliability.

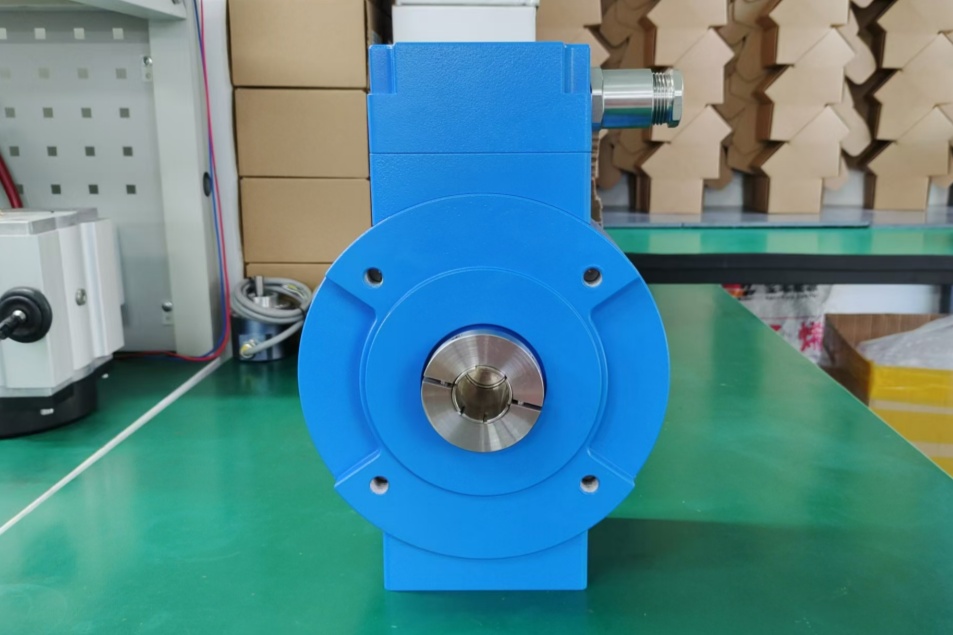

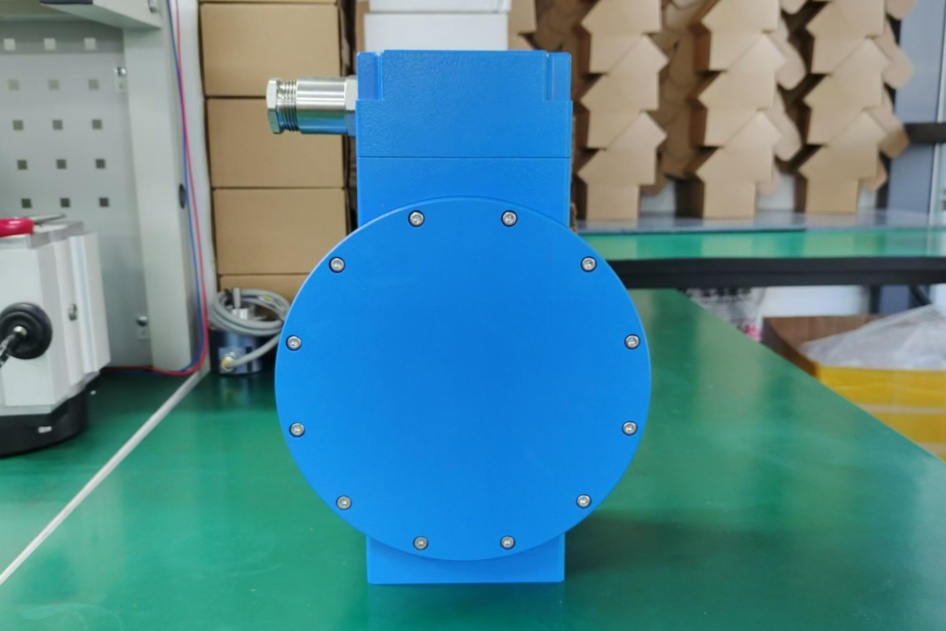

Actual photos of the replacement product.

Introduction

Avtron M6C explosion protected ATEX and IECEx rated severe mill duty rotary encoders are designed for direct mounting on motor or load shafts, from 1" to 1 1/8" [25-30mm].

The M6C is an updated model which directly replaces the M6 encoder, and M6C adds IECEx certification. No barrier or isolator is required-mount M6C directly in any ATEX or IECEx Zone 1 application.

Why take a chance with weak optical encoders on your drilling rig? The M6C features Avtron Encoders' rugged magnetic sensor and solid metal rotor technology. Our shatterproof, moisture proof systems ensure your application has maximum uptime. The hollow shaft (tethered) models offer direct mounting on shafts from 1" to 1 1/8", without flanges, reducers, couplings, or other hardware. No rework is needed; just mount the encoder directly on the shaft, and secure the tether arm. The heavy duty bearings withstand runout and vibration that destroy lesser encoders.

M6C also includes a complete wiring protection system--it can survive all types of wiring errors and drive signals down the longest cables.

For more information on keeping your rotary encoders working in oil and gas applications, visit our oil and gas blog.

We believe explosion protected encoders should also be ready to withstand the rough drilling environment. Try the M6C today!

Parameters

Operating Power: Volts: 5-24 VDC; Current: 120mA, no load

Output Format: A, /A, B, /B; Optional Marker Z, /Z

Frequency Range: 0 to 250 kHz @ 6 V & 1 meter cable

PPR: 240-1200

Speed: 5000 RPM Max. Std.

Temperature: 80°C to -40°C (-40°C optional, -20°C standard)

Chemical: Polyurethane enamel paint protects against salt spray, mild acids, and bases

Enclosure Rating: IP66

Explosion Protection:

ATEX 0539 II 2 G Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

IECEx Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

Weight: 18 lbs. / 8kg.