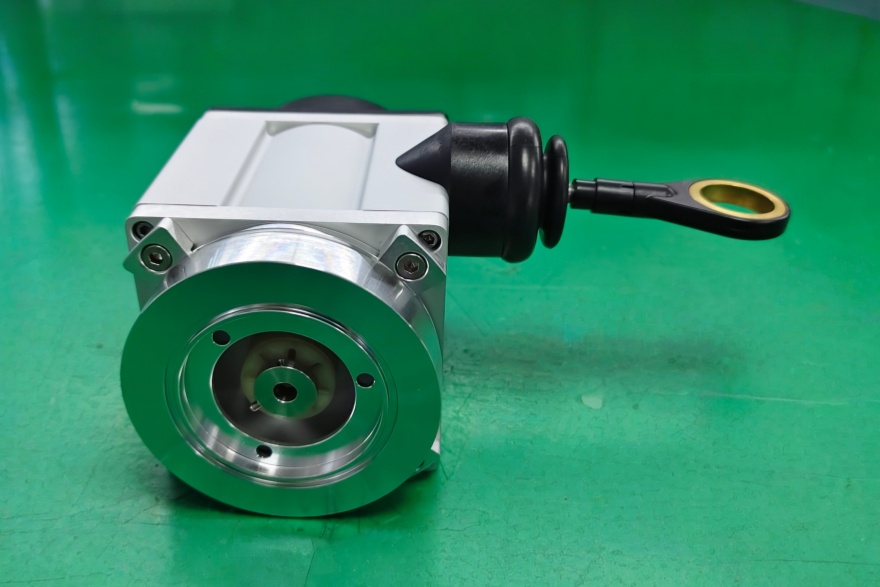

The MRA-F130-105D2 wire draw encoder can be replaced with our precision-engineered draw wire displacement sensor, designed to replicate the mechanical and functional characteristics of the original unit. This replacement provides reliable absolute position measurement and stable operation, allowing seamless integration into existing systems. The standard production and delivery time is approximately 10 working days, providing a fast and dependable solution for maintenance or system upgrades.

Constructed with a durable cable mechanism and precision internal components, this sensor delivers smooth, repeatable measurements and long-term operational stability. It is suitable for industrial applications such as machinery positioning, stroke monitoring, and linear motion detection, offering consistent and accurate performance even under demanding operating conditions.

Detailed technical data

| Параметр | Подробности |

|---|---|

| Описание | HighLine wire draw mechanism for servo flange with 6 mm shaft, measuring range 0 m ... 5 m |

| Items supplied | Without encoder |

| Диапазон измерений | 0 m ... 5 m |

| Reproducibility | ≤ 1 mm |

| Линейность | ≤ ± 2 мм |

| Гистерезис | ≤ 2 mm |

| Вес | 1.5 kg Wire draw mechanism |

| Вес (измерительная проволока) | 7,1 г/м |

| Материал измерительной проволоки | Высокогибкая многожильная сталь 1.4401 из нержавеющей стали V4A |

| Material, spring housing | Die-cast zinc |

| Материал корпуса, механизм протяжки проволоки | Aluminum (anodized), aluminum die cast (nickel-plated) |

| Длина проволоки, вытягиваемой за один оборот | 200 мм |

| Фактическая длина протяжки проволоки | 5.2 m |

| Возвратная сила пружины | 6 N ... 14 N 1) |

| Измерение диаметра проволоки | 1,35 мм |

| Ускорение проводов | 40 м/с² |

| Рабочая скорость | 8 м/с |

| Разрешение | To calculate the resolution of the system please use following formula:length of wire draw per revolution / steps per revolution = resolution of the combination of wire draw + encoder |

| Ambient operating temperature | -30 °C ... +70 °C |

| Enclosure rating mechanic | IP64 |

| Срок службы механизма протяжки проволоки | Тип. 1,000,000 циклов 2), 3) |