For the HOG163M DN 2048 I 75H7, we provide a fully customized HTL encoder replacement solution, built to match all essential characteristics of the original unit. The 1:1 design replicates the original shaft, flange, and electrical outputs, enabling straightforward integration into existing systems. Production requires 15 working days, offering a dependable schedule for industries needing timely access to high-quality replacement encoders.

With 2048 pulses per revolution, this encoder is engineered for mid-resolution applications including industrial drives, robotic systems, and heavy machinery where consistent incremental feedback is critical. Its hollow shaft, optical sensing, and robust light-metal housing ensure reliable performance even under challenging operational conditions. Additional features such as a rotatable terminal box and corrosion protection increase flexibility and longevity, making this replacement unit a practical solution for maintaining precise motion control across a variety of industrial applications.

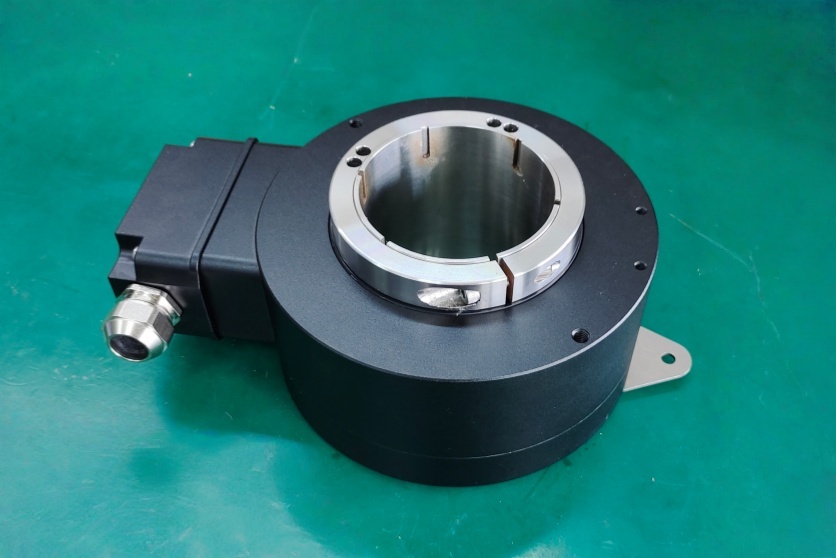

Reference Images

Technical data - electrical ratings

| Voltage supply | 9..30 VDC 5VDC+5% 9...26 VDC |

|---|---|

| Consumption w/o load | ≤100mA |

| Pulses per revolution | 250....2500 |

| Phase shift | 90°+20° |

| Duty cycle | 40...60% |

| Reference signal | Zero pulse,width 90° |

| Sensing method | Optical |

| Output frequency | S120 kHz |

| Output signals | K1,K2,KO+inverted |

| Output stages | HTL TTL/RS422 |

| Interference immunity | EN61000-6-2 |

| Emitted interference | EN61000-6-3 |

| Approval | CE UL approval/E217823 |

Technical data - mechanical design

| Protection EN 60529 | IP54 |

|---|---|

| Operating speed | S6000 rpm (mechanical) |

| Operating torque typ. | 15 Ncm |

| Rotor moment of inertia | 26.3 kgcm2(48) 13.5 kgcm2(75) |

| Material | Housing: aluminium alloy Shaft: stainless steel |

| Operating temperature | -40..+85℃ |

| Resistance | IEC 60068-2-6 Vibration 10g, 10-2000 Hz IEC 60068-2-27 Shock 100 g,6ms |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions C4 according to ISO12944-2 |

| Explosion protection | I13G Ex ec IIC T4 Gc (gas) I1 3 D Extc II T10C Dc(dust) (only with option ATEX) |

| Connection | Terminal box 2x terminal box (with option M) |

| Weight approx. | 4.5kg (048) 3.2kg(075) 3.6 kg (o75 with option M) |