Bu FG40K-8192G-90G-NG is a widely recognized incremental encoder designed for heavy-duty applications in the steel and metallurgy industry. With a resolution of 8192 pulses per revolution, this encoder delivers high precision, making it suitable for demanding automation and control tasks. For decades, it has been one of the reliable choices for operators who need both accuracy and durability in harsh industrial environments.

One of the key strengths of this encoder lies in its ability to perform consistently under extreme conditions. Steel plants, rolling mills, and casting lines often operate in environments filled with vibration, dust, oil, and high temperatures. Standard encoders often fail in such environments, but the FG40K-8192G-90G-NG is specifically engineered to withstand these challenges. It provides a steady output signal even when exposed to continuous stress, making it a trusted component in critical production lines.

In terms of technical performance, the 8192 PPR resolution makes it an excellent choice for fine positioning and speed monitoring. It is often used in drive systems, conveyor synchronization, and precision motion control. Whether it is a rolling mill that requires exact speed alignment or a casting line that needs precise feedback, this encoder ensures that operators maintain full control of their processes.

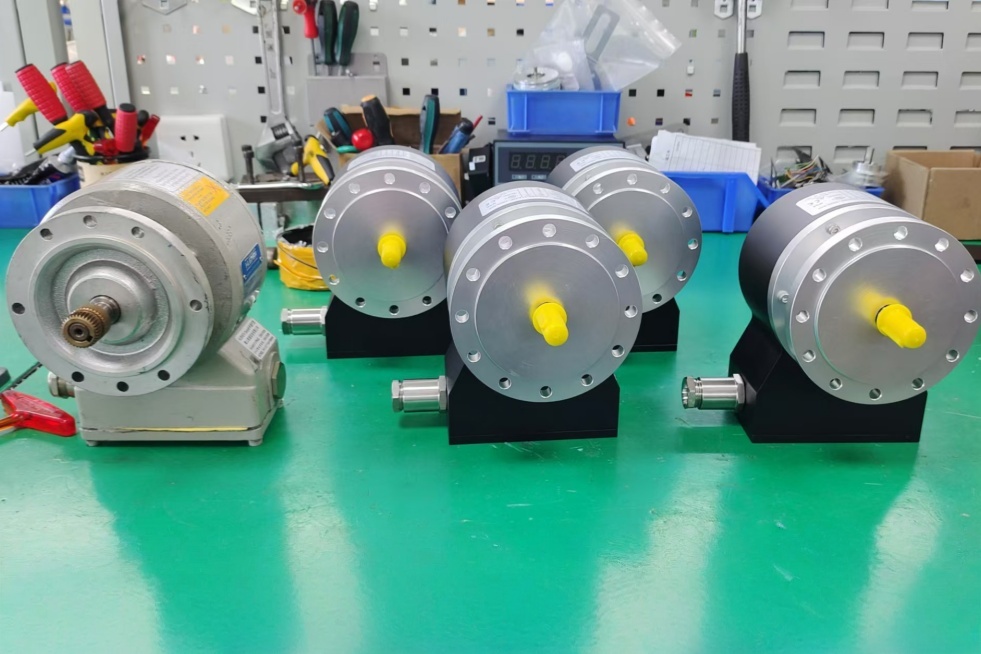

However, many companies face procurement difficulties when sourcing this model. Lead times for heavy-duty encoders are often long, and in urgent cases, delays can result in costly downtime. To address this problem, we provide a custom-built replacement encoder designed to mirror the original FG40K-8192G-90G-NG in both mechanical and electrical specifications. This ensures plug-and-play compatibility without requiring any modification to existing systems.

Our replacement encoders are manufactured with industrial-grade materials and undergo rigorous quality testing. The result is a solution that not only matches the performance of the original but also provides excellent stability and long service life. This makes our encoder replacements a dependable choice for operators who cannot compromise on reliability in heavy-duty steel production environments.

We also support non-standard customization services, which means we can adapt encoders to meet special requirements such as unique shaft dimensions, output signal types, or connector options. By offering this flexibility, we ensure that our customers can keep their production systems running smoothly, even when their applications require special technical solutions.

FAQ – Common Questions about FG40K-8192G-90G-NG Replacements

Q: What industries typically use the FG40K-8192G-90G-NG encoder?

A: It is mainly applied in steel mills, metallurgy plants, and heavy-duty machinery, where precision and durability are critical.

Q: Can the replacement encoder be customized for non-standard setups?

A: Yes, we provide tailor-made encoders based on customer requirements, covering electrical, mechanical, and connector variations.

Q: How fast can a replacement encoder be delivered?

A: Our average lead time is 15 working days, which is significantly shorter than standard procurement cycles.

In summary, the FG40K-8192G-90G-NG custom replacement is an ideal solution for operators struggling with supply delays. By offering non-standard customization and a 15-day delivery cycle, we help steel and metallurgy companies maintain production continuity, reduce procurement risks, and ensure long-term system reliability.