8.A12C.68C2.C212 Multiturn Absolute Encoder Custom Replacement

Custom Replacement Capability

The 8.A12C.68C2.C212 multiturn absolute encoder is available as a custom replacement solution that matches the original unit in mechanical and electrical specifications. Our production cycle is approximately fifteen working days, allowing customers to reduce downtime and maintain uninterrupted operations. The replacement unit preserves mounting dimensions, shaft interface, and signal output, enabling seamless integration into existing systems.

Product Overview

This encoder provides high-resolution absolute position feedback across multiple rotations of the shaft. It retains absolute position information even after power loss, ensuring reliable performance without the need for recalibration. Supported communication interfaces include SSI, Profibus, and CANopen. The robust housing and high-quality bearings ensure long-term durability in demanding industrial environments. The encoder’s multiturn functionality allows precise monitoring of extended rotations, which is ideal for automation and motion control applications that require consistent and repeatable position feedback.

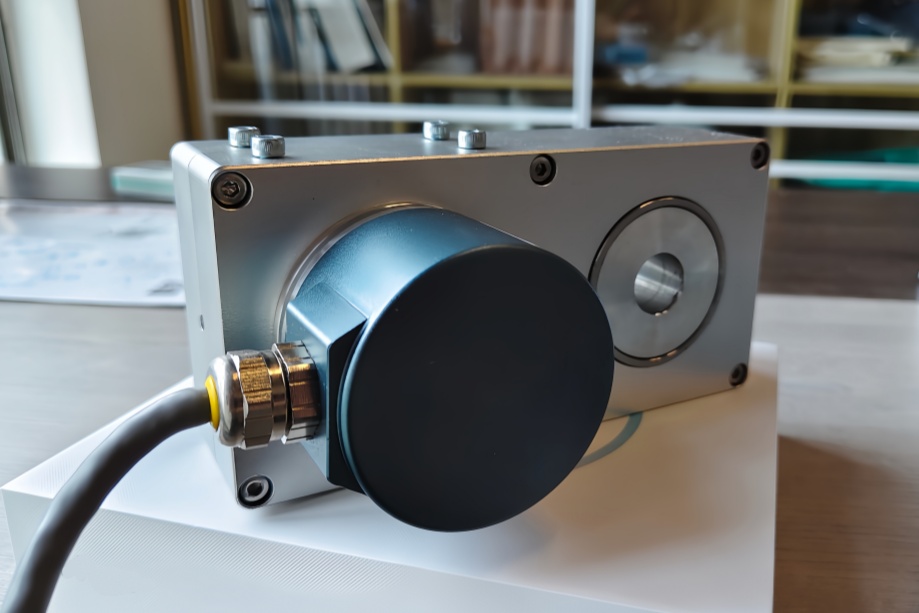

Visual Note

Customized product real photos available.

Industrial Applications

The 8.A12C.68C2.C212 is used in heavy industries such as steel production, cranes, automated conveyors, wind energy, and robotics. It enables precise roller positioning, hoist operations, and material handling synchronization. Crane systems utilize the encoder to ensure accurate cable winding, while wind turbines rely on it for blade pitch and nacelle rotation monitoring. Robotic and packaging systems benefit from consistent, high-resolution feedback during repeated operations. Its reliability in continuous operation enhances productivity and reduces maintenance requirements.

Our Advantage

Our replacement solution is cost-effective, reliable, and customizable. Electrical interfaces, resolution, and mechanical design can be tailored to specific requirements. Production lead times are short, ensuring timely delivery. The encoder’s robust construction guarantees long-term performance, providing a dependable alternative to original units while maintaining high precision and operational continuity.