The FG40K-5000G-90G-NG is a high-resolution incremental encoder, offering 5000 pulses per revolution for advanced control in heavy-duty industrial applications. It is widely used in steel rolling mills, casting lines, and other automation systems where accuracy and reliability are crucial.

Its robustness allows it to operate effectively under vibration, dust, oil, and extreme temperatures, making it ideal for continuous production lines in steel plants and metallurgical facilities. Operators trust this encoder for precise speed control and position monitoring, ensuring consistent output quality.

From a technical standpoint, the encoder delivers stable electrical signals and precise feedback, essential for high-performance automation. Its high resolution supports fine-tuned adjustments in drive systems, conveyor synchronization, and heavy-duty machinery, reducing waste and improving efficiency.

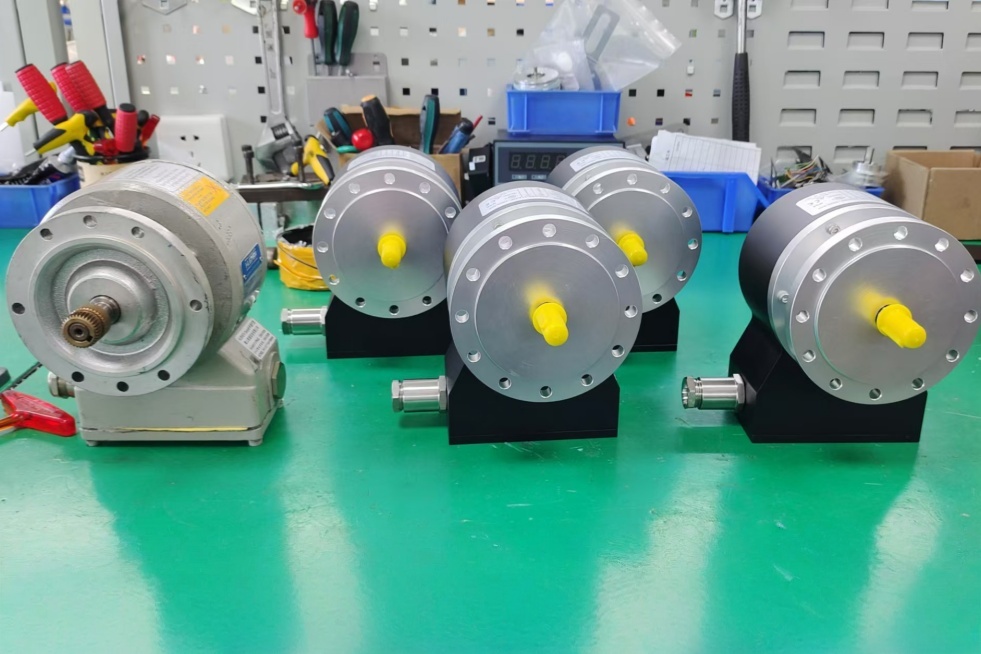

Recognizing that supply chain delays often threaten production, we offer a custom replacement solution that replicates the original’s mechanical and electrical parameters. This allows direct integration into existing equipment, minimizing downtime and avoiding system redesign.

Our replacements are made from industrial-grade materials, tested for long-term stability and reliability. This ensures they maintain consistent performance in demanding heavy-industry operations, giving operators confidence in uninterrupted production.

FAQ – FG40K-5000G-90G-NG

Q: Can this encoder be customized for unique installation requirements?

A: Yes, our solutions can be tailored for shaft dimensions, connector types, and output signals.

Q: How quickly can a custom replacement be delivered?

A: Typical lead time is 15 working days, ensuring timely availability for critical operations.

In conclusion, the FG40K-5000G-90G-NG custom encoder provides precision, durability, and fast availability. With non-standard customization and a 15-day lead time, it offers steel industry operators a reliable solution to procurement challenges.