The AMS4K-1212 is an industrial-grade encoder model that has become difficult to procure in recent years, especially for companies operating in the metallurgical and heavy machinery sectors. To address this problem, we provide a non-standard customized replacement solution with 1:1 parameter matching to the original specifications. This ensures that our replacement encoder can be seamlessly integrated into existing systems without additional modifications. Customers who are unable to source the original AMS4K-1212 can rely on our solution to restore normal operation with minimal downtime. Our production process is optimized to shorten lead times, allowing for rapid delivery even in urgent projects.

In terms of application, the AMS4K-1212 encoder was designed for use in heavy-duty industrial environments such as rolling mills, continuous casting machines, and steel processing systems. It delivers accurate and stable incremental feedback, essential for maintaining precise motion control and synchronization in complex machinery. Thanks to its robust construction and proven performance, it has long been trusted by engineers and plant operators. Even though original models may no longer be readily available, our customized replacement encoders are engineered to maintain the same durability and precision, ensuring consistent performance under vibration, dust, and high-temperature conditions typical of steel production lines.

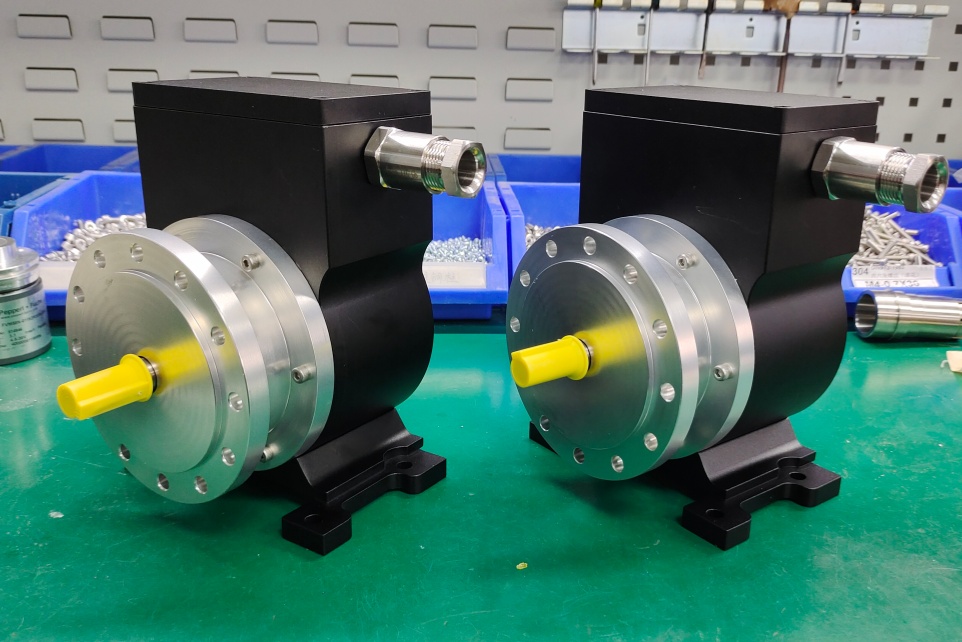

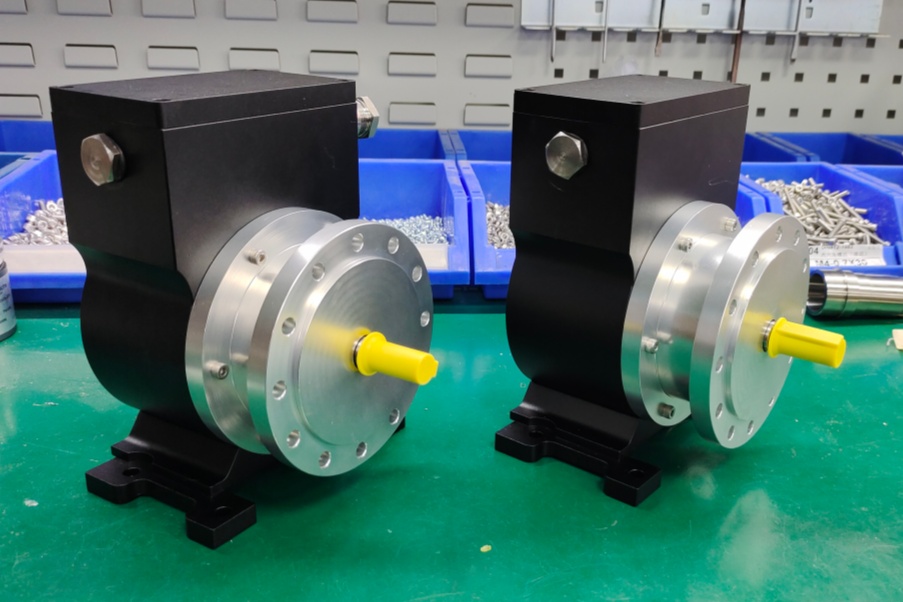

Replacement solution reference image.

Technical data

1. Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12…30 V DC |

| No-load power consumption | approx. 1 W |

| Resolution singleturn | Max. 16 bit (65536 steps per revolution) see type plate |

| Resolution multiturn | 12 bit (4096 revolutions) see type plate |

| Data format | SSI, binary/gray code (see type plate) |

2. SSI-Interface

| Parameter | Details |

|---|---|

| Clock input | RS 422 / 5V |

| Input current | 5 mA |

| Clock frequency | 80kHz…1 MHz |

| Clock rate/transmission | 25 / 13 (multiturn / singleturn) |

| SSI-time out | > 30 μs (without data repetition) < 20 μs (with data repetition) |

| Data interface | RS 422 / 5V |

3. Control signals

| Parameter | Details |

|---|---|

| V/IR, Z (input) | 5…30V / 5mA |

| State (output) | HTL |

| Temperature range | -25°C…+85°C; For UL and CSA -25°C…+70°C |

4. Degree of protection according to DIN EN 60529

| Degree of protection | Sealing | Mech. permissable speed | Rotor moment of inertia | Breakaway torque |

|---|---|---|---|---|

| IP 66 | with Labyrinth seal | ≤6000 rpm | approx. 580 gcm² | approx. 6 Nm |

| IP 66 / IP 67 | with axial shaft seal | ≤4000 rpm | approx. 510 gcm² | approx. 8 Nm |

| IP 66 / IP 67 | With radial shaft seal (for special applications, e.g. wet areas in rolling mills) | ≤3000 rpm | approx. 510 gcm² | approx. 9 Nm |

5. Vibration resistance, shock resistance and shaft load

| Parameter | Standard | Value |

|---|---|---|

| Vibration resistance | DIN EN 60068-2-6 / IEC 68-2-6 (10 … 2000 Hz) | 20 g (=200 m/s²) |

| Shock resistance | DIN EN 60068-2-27 / IEC 68-2-27 (6 ms) | 150 g (=1500 m/s²) |

| Max. encoder shaft load | - | Fₐ, max. (axial) = 100 N; Fᵣ, max. (radial) = 120 N |

6. Shaft dimensions

| Parameter | Details |

|---|---|

| Shaft dimensions | 11j6 x 30 mm (standard); 14j6 x 30 mm (optional) |

7. Weight

| Parameter | Type | Details |

|---|---|---|

| Weight | Type K (construction type B5) | approx. 3.1 kg |