The AMS40K-1212 incremental encoder has become increasingly difficult to procure in the industrial market, especially for companies in the steel and metallurgical sectors that rely on it for critical automation processes. To address this sourcing challenge, we offer a fully customized 1:1 replacement solution that replicates the exact parameters and performance of the original AMS40K-1212 model. This non-standard customized approach ensures direct mechanical and electrical compatibility, enabling customers to install the replacement encoder without modifying their existing systems. Our streamlined production process helps shorten delivery time, ensuring rapid response for urgent maintenance and production needs.

From an application standpoint, the AMS40K-1212 encoder was widely used in high-demand environments such as steel rolling mills, casting lines, and industrial drive systems. It is known for its precision in providing stable incremental feedback for speed and position control in heavy-duty equipment. The encoder’s robust construction and ability to endure vibration, dust, and heat made it a trusted choice for long-term operation in challenging conditions. For users still running legacy machinery that depends on this model, our replacement encoders provide a seamless way to maintain production stability without compromising accuracy or durability.

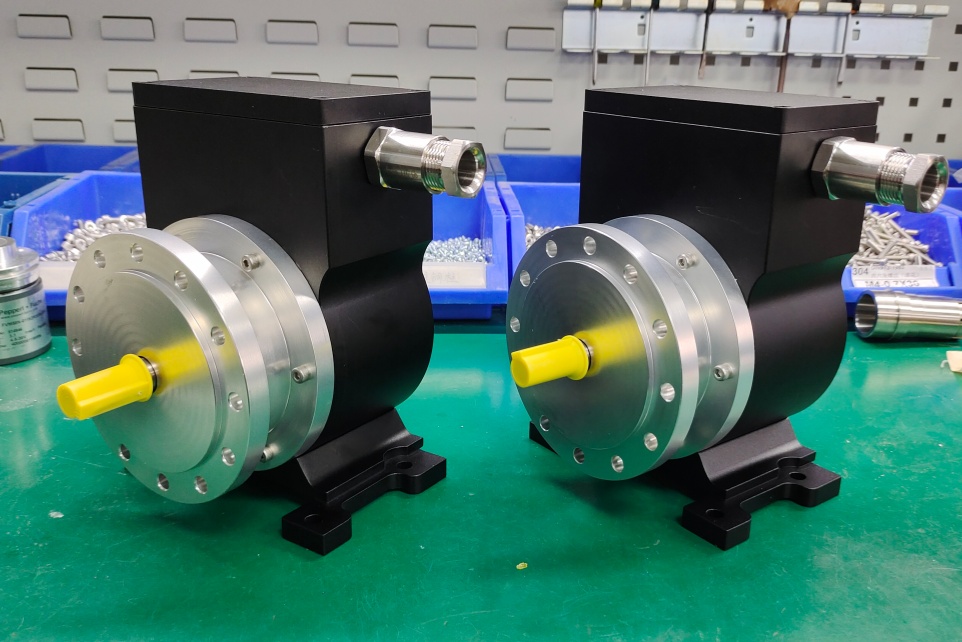

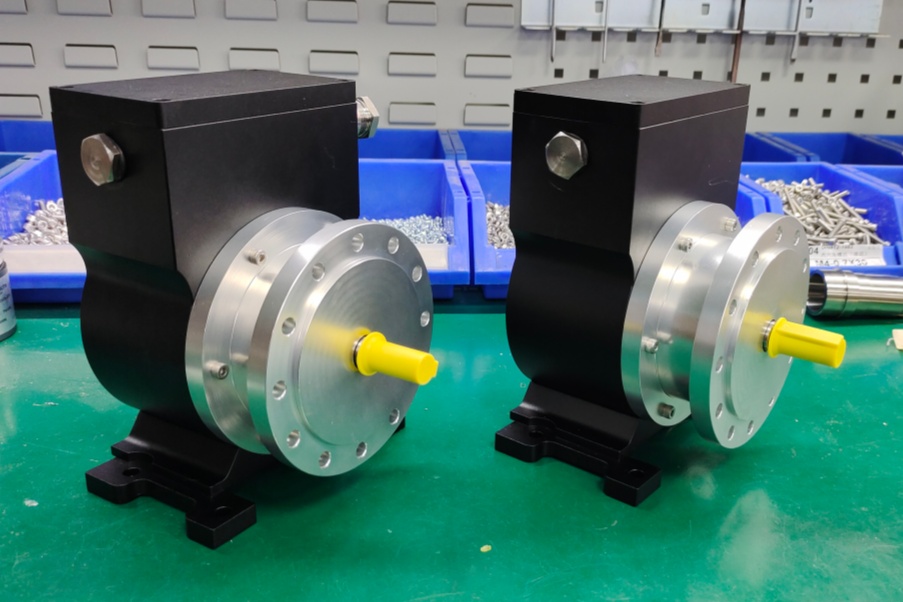

Replacement solution reference image.

Technical data

1. Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12…30 V DC |

| No-load power consumption | approx. 1 W |

| Resolution singleturn | Max. 16 bit (65536 steps per revolution) see type plate |

| Resolution multiturn | 12 bit (4096 revolutions) see type plate |

| Data format | SSI, binary/gray code (see type plate) |

2. SSI-Interface

| Parameter | Details |

|---|---|

| Clock input | RS 422 / 5V |

| Input current | 5 mA |

| Clock frequency | 80kHz…1 MHz |

| Clock rate/transmission | 25 / 13 (multiturn / singleturn) |

| SSI-time out | > 30 μs (without data repetition) < 20 μs (with data repetition) |

| Data interface | RS 422 / 5V |

3. Control signals

| Parameter | Details |

|---|---|

| V/IR, Z (input) | 5…30V / 5mA |

| State (output) | HTL |

| Temperature range | -25°C…+85°C; For UL and CSA -25°C…+70°C |

4. Degree of protection according to DIN EN 60529

| Degree of protection | Sealing | Mech. permissable speed | Rotor moment of inertia | Breakaway torque |

|---|---|---|---|---|

| IP 66 | with Labyrinth seal | ≤6000 rpm | approx. 580 gcm² | approx. 6 Nm |

| IP 66 / IP 67 | with axial shaft seal | ≤4000 rpm | approx. 510 gcm² | approx. 8 Nm |

| IP 66 / IP 67 | With radial shaft seal (for special applications, e.g. wet areas in rolling mills) | ≤3000 rpm | approx. 510 gcm² | approx. 9 Nm |

5. Vibration resistance, shock resistance and shaft load

| Parameter | Standard | Value |

|---|---|---|

| Vibration resistance | DIN EN 60068-2-6 / IEC 68-2-6 (10 … 2000 Hz) | 20 g (=200 m/s²) |

| Shock resistance | DIN EN 60068-2-27 / IEC 68-2-27 (6 ms) | 150 g (=1500 m/s²) |

| Max. encoder shaft load | - | Fₐ, max. (axial) = 100 N; Fᵣ, max. (radial) = 120 N |

6. Shaft dimensions

| Parameter | Details |

|---|---|

| Shaft dimensions | 11j6 x 30 mm (standard); 14j6 x 30 mm (optional) |

7. Weight

| Parameter | Type | Details |

|---|---|---|

| Weight | Type K (construction type B5) | approx. 3.1 kg |