The AMS40K-1312 SSI absolute encoder can be provided as a 1:1 customized replacement solution, with a standard production lead time of 10 working days. Our replacement model is designed to precisely match the original encoder’s mechanical dimensions, shaft configuration, and SSI communication interface, ensuring direct electrical and mechanical compatibility. This plug-and-play solution allows users to install the replacement encoder effortlessly without modifying system wiring or control parameters.

From a technical standpoint, the AMS40K-1312 encoder delivers high-resolution absolute position feedback and stable SSI signal transmission, making it suitable for heavy-duty industrial applications such as steel processing, paper manufacturing, and large-scale automation systems. Its rugged construction and precision engineering ensure exceptional performance and reliability, even under conditions of high vibration and temperature variation. Our replacement encoders have been successfully deployed in South America, Southeast Asia, the Middle East, Indonesia, and Russia, where they are recognized for their durability and long-term stability.

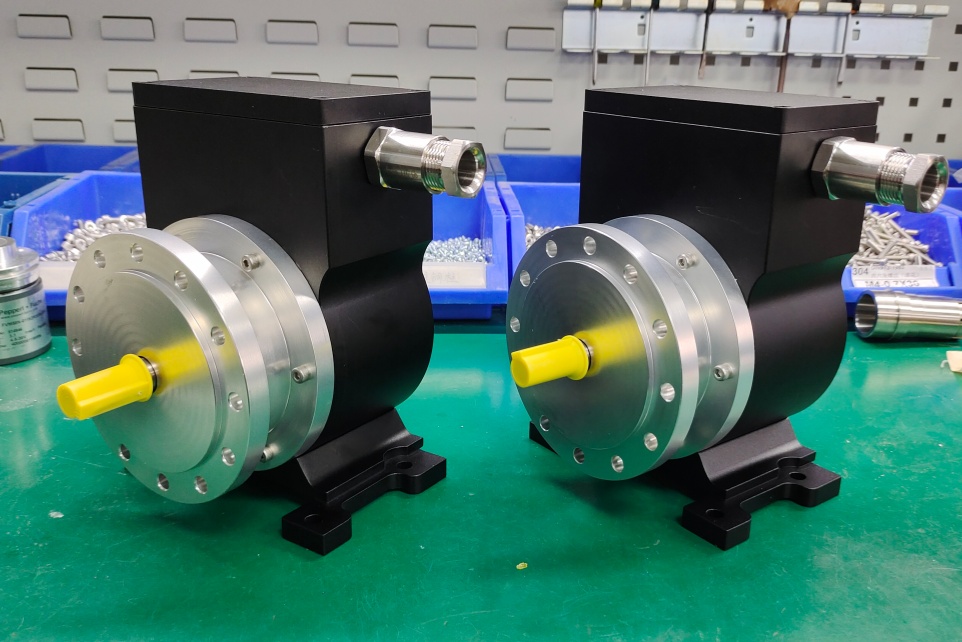

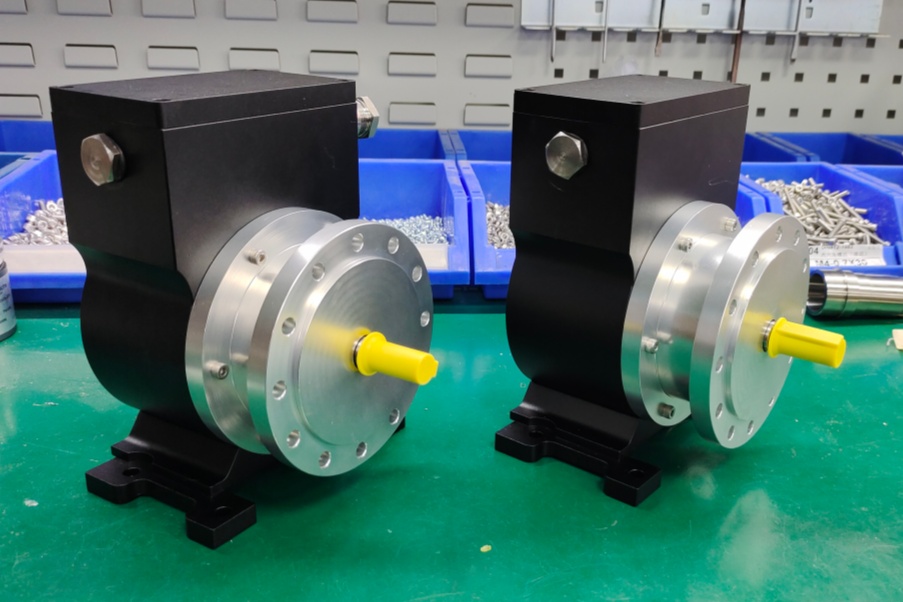

Replacement solution image

Technical data

1. Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12…30 V DC |

| No-load power consumption | approx. 1 W |

| Resolution singleturn | Max. 16 bit (65536 steps per revolution) see type plate |

| Resolution multiturn | 12 bit (4096 revolutions) see type plate |

| Data format | SSI, binary/gray code (see type plate) |

2. SSI-Interface

| Parameter | Details |

|---|---|

| Clock input | RS 422 / 5V |

| Input current | 5 mA |

| Clock frequency | 80kHz…1 MHz |

| Clock rate/transmission | 25 / 13 (multiturn / singleturn) |

| SSI-time out | > 30 μs (without data repetition) < 20 μs (with data repetition) |

| Data interface | RS 422 / 5V |

3. Control signals

| Parameter | Details |

|---|---|

| V/IR, Z (input) | 5…30V / 5mA |

| State (output) | HTL |

| Temperature range | -25°C…+85°C; For UL and CSA -25°C…+70°C |

4. Degree of protection according to DIN EN 60529

| Degree of protection | Sealing | Mech. permissable speed | Rotor moment of inertia | Breakaway torque |

|---|---|---|---|---|

| IP 66 | with Labyrinth seal | ≤6000 rpm | approx. 580 gcm² | approx. 6 Nm |

| IP 66 / IP 67 | with axial shaft seal | ≤4000 rpm | approx. 510 gcm² | approx. 8 Nm |

| IP 66 / IP 67 | With radial shaft seal (for special applications, e.g. wet areas in rolling mills) | ≤3000 rpm | approx. 510 gcm² | approx. 9 Nm |

5. Vibration resistance, shock resistance and shaft load

| Parameter | Standard | Value |

|---|---|---|

| Vibration resistance | DIN EN 60068-2-6 / IEC 68-2-6 (10 … 2000 Hz) | 20 g (=200 m/s²) |

| Shock resistance | DIN EN 60068-2-27 / IEC 68-2-27 (6 ms) | 150 g (=1500 m/s²) |

| Max. encoder shaft load | - | Fₐ, max. (axial) = 100 N; Fᵣ, max. (radial) = 120 N |

6. Shaft dimensions

| Parameter | Details |

|---|---|

| Shaft dimensions | 11j6 x 30 mm (standard); 14j6 x 30 mm (optional) |

7. Weight

| Parameter | Type | Details |

|---|---|---|

| Weight | Type K (construction type B5) | approx. 3.1 kg |