The MRA-G055-101D4 1:1 replacement solution is engineered as a fully compatible wire-draw mechanism designed to match the performance and installation requirements of the original SICK unit. It supports a measuring range of 1.25 meters and delivers high repeatability with a typical reproducibility of ≤0.2 mm. The mechanism uses a stainless-steel sheathed measuring wire with a diameter of 0.45 mm, ensuring durability and stable measurement even under continuous operation. With a wire-per-revolution value of 150 mm and a maximum operating speed of 6 m/s, it provides reliable performance for linear positioning applications across various automation environments.

The mechanism features a compact, lightweight housing made from impact-resistant engineering plastic, combined with a long-life spring return system rated for up to one million cycles. It operates within a broad temperature range of –30 °C to +70 °C, making it suitable for harsh industrial conditions. Designed for direct integration with compatible absolute or incremental encoders, this 1:1 replacement ensures seamless mounting and consistent measurement results without requiring system modifications. It is an ideal choice for maintaining equipment uptime when the original MRA-G055-101D4 becomes difficult to source.

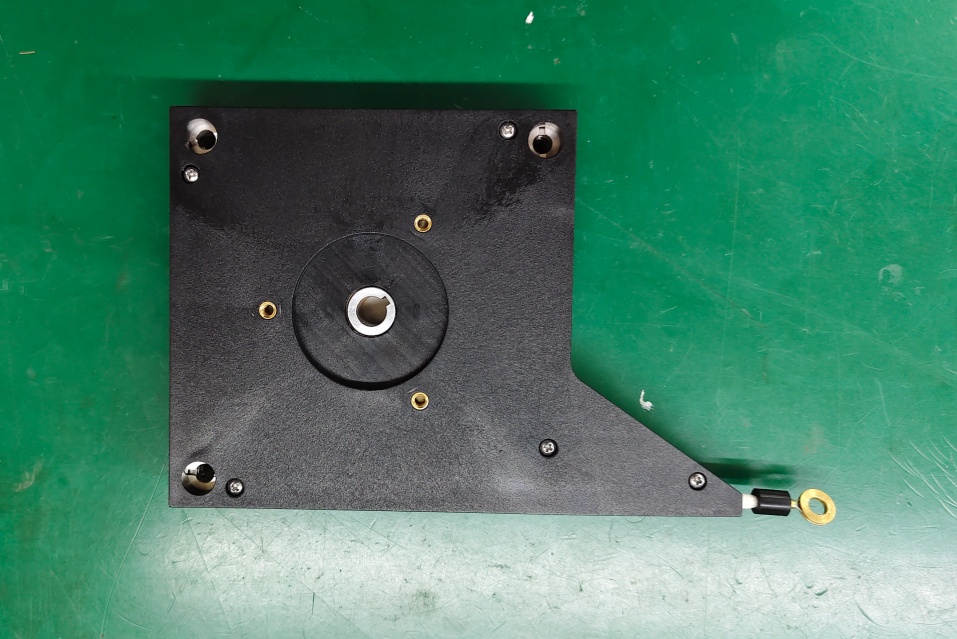

Replacement solution image

Technical details

| Description | EcoLine wire draw mechanism for servo flange with 6 mm shaft, measuring range 0 m ... 1.25 m |

| Items supplied | Without encoder, 2 x fixing clamp (0061W01-00:21), 2 x fixing screw (DIN912-M3x6), 1 x Woodruff key DIN 6888 2x2.6 |

| Measurement range | 0 m ... 1.25 m |

| Reproducibility | ≤ 0.2 mm |

| Linearity | ≤ ± 2 mm |

| Hysteresis | ≤ 0.4 mm |

| Weight | 80 g |

| Wire draw mechanism Weight (measuring wire) | 0.58 g/m |

| Measuring wire material | Highly flexible stranded steel 1,4401 stainless steel V4A/PA 12-sheathed |

| Housing material | Plastic, Noryl |

| Housing material, wire draw mechanism | Plastic, Noryl |

| Length of wire pulled out per revolution | 150 mm |

| Actual wire draw length | 1.45 m |

| Spring return force | 1 N ... 1.4 N 1) |

| Measuring wire diameter | 0.45 mm |

| Wire acceleration | 10 m/s² |

| Operating speed | 6 m/s |

| Resolution | To calculate the resolution of the system please use following formula: length of wire draw per revolution / steps per revolution = resolution of the combination of wire draw + encoder |

| Ambient operating temperature | –30 °C ... +70 °C |

| Enclosure rating mechanic | IP50 |

| Life of wire draw mechanism | Typ. 1,000,000 cycles 2) 3) |