The FG4KK-1200G-90G-NG is a precision incremental encoder designed for steel production lines, metallurgical automation systems, and medium-to-heavy industrial machinery. With 1,200 pulses per revolution, it delivers accurate and stable feedback for speed control, position monitoring, and drive synchronization in applications such as conveyors, rolling mills, and motor drives. Its durable construction allows it to perform reliably in high-temperature, high-vibration, and dust-laden environments common in steel plants.

Because the original model has become difficult to procure, our team developed a custom replacement encoder that exactly matches the original’s specifications. This includes mechanical dimensions, electrical interfaces, and incremental signal output characteristics, allowing for a direct replacement without modification to existing machinery. By providing a drop-in solution, we help steel industry operators reduce maintenance downtime and avoid costly production interruptions.

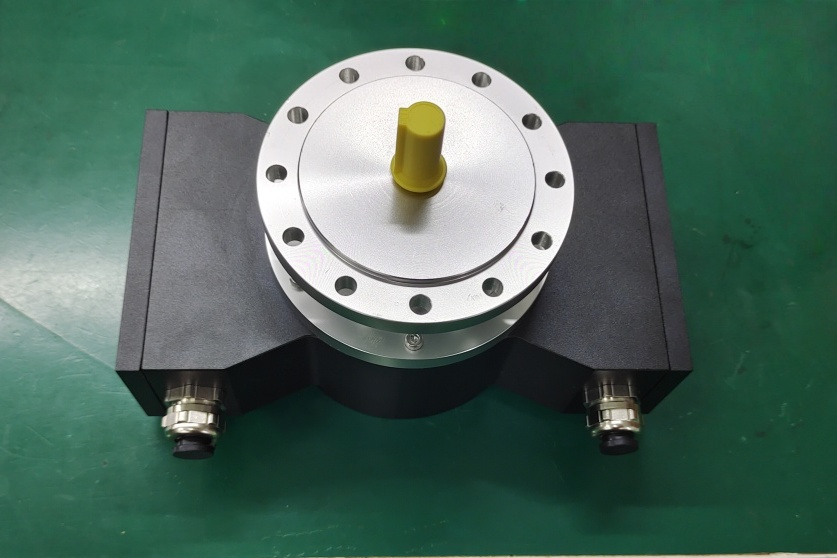

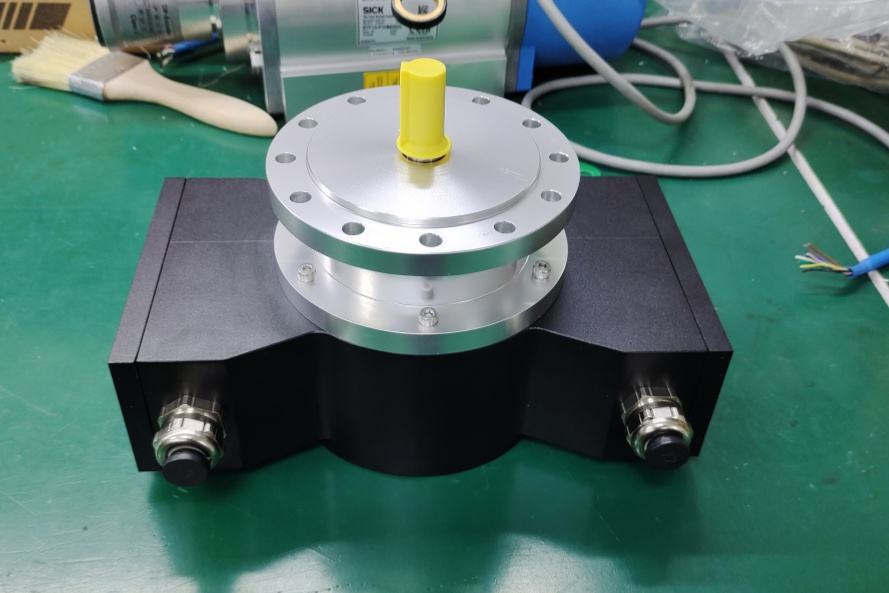

Alternative Solution Product Image

Applications:

Steel rolling lines requiring synchronized motion control

Conveyor systems in high-load metallurgical environments

Heavy-duty motor drives for continuous operation

Automation systems in steel and metallurgy plants

Expert’s note: The FG4KK-1200G-90G-NG is valued for its balanced resolution and durability, providing precise feedback while withstanding the demanding conditions of steel production. Our replacement solution ensures long-term availability, allowing clients to maintain operational efficiency and reduce dependency on scarce legacy components. Additionally, our customization service allows adaptation to unique operational requirements, further enhancing the reliability of steel processing equipment.

Recognizing the difficulty of sourcing legacy encoders, we provide non-standard custom order services for the FG4KK-1200G-90G-NG. Clients can commission encoders specifically designed to meet their operational needs, avoiding delays in production lines. Typically, our non-standard delivery period is 15 working days, offering a fast, reliable alternative for operators in steel production and metallurgical automation systems.

Technical Datasheet

Pulse rates

| Category | Value |

|---|---|

| Standard pulse rates | 500, 600, 1000, 1024, 1200, 2000, 2048, 2400, 2500 |

| Special pulse rates | 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000(further pulse rates according to customers specification) |

Connection data

| Parameter | Details |

|---|---|

| Supply voltage | 12 V … 30 V DCFor UL and CSA Class 2 supplied |

| No load-current | approx. 50 mA at 24 V |

| Outputs | Current limited, short-circuit proof push-pull line driver with integrated impedance adaptation for 30 to 140 Ω lines. |

| Pulse height (HTL) | approx. as supply voltage, output saturation voltage < 0.4 V at Iₗ 30 mA |

| Output current | max. 150 mA at 24 V (observe derating) |

| Internal resistance | 75 Ω bei 24 V |

| Slew rate | 200 V / μs with Cₗ 100 pF |

| Duty cycle | 1:1 ± 3 % for standard pulse rates1:1 ± 5 % for special pulse rates up to 25000 pulses |

| Square wave displacement 0°, 90° | 90° ± 3 % for standard pulse rates90° ± 5 % for special pulse rates up to 25000 pulses |

| Max. frequency | 200 kHz, Higher max. frequency on request |

Special output voltage 5V (TTL)

| Parameter | Details |

|---|---|

| Pulse height | 5V, RS422-compatible (TIA/EIA - Standard) |

| Supply voltage | 12 … 30 V DC (optional: 5 V DC)For UL and CSA Class 2 supplied |